Main specification

| Heading | Contents | |||

|---|---|---|---|---|

| 3-axis type | 4-axis type | |||

| Maximum load capacity (kg) (Note1) | 3 | |||

| Speed (Note2) | Maximum resultant speed (mm/s) | 5529 | ||

| Maximum speed of each axis | 1st arm (degree/s) | 660 | ||

| 2nd arm (degree/s) | 660 | |||

| Vertical axis (mm/s) | 1400 | |||

| Rotating axis (degree/s) | - | 1600 | ||

| Push force (N) (Note3) | Upper limit | 60 | ||

| Minimum | 10 | |||

| Arm length (mm) | 300 | |||

| Arm length of each axis (mm) | 1st arm | 120 | ||

| 2nd arm | 180 | |||

| Operating range of each axis | 1st arm (degree) | ±135 | ||

| 2nd arm (degree) | ±142 | |||

| Vertical axis (mm) | 150 | |||

| Rotating axis (degree) | - | ±360 | ||

| Heading | Contents | ||

|---|---|---|---|

| 3-axis type | 4-axis type | ||

| Repeated positioning accuracy (Note4) | Horizontal plane | ±0.01mm | |

| Vertical axis | ±0.01mm | ||

| Rotating shaft | - | ±0.005 degree | |

| User wiring | 10-core (9-core + shield) AWG24 (Rated 30V / Max. 1A) | ||

| User piping | Air tube (O.D. ø4, I.D. ø2.5) x 3 (Maximum working pressure 0.6 MPa) | ||

| Alarm indicator light (Note 5) | Optional (1 small amber LED indicator light (24V DC supply required)) | ||

| Brake release switch (Note 6) | Brake release switch for vertical axis fall prevention | ||

| Tip shaft | Allowable torque | 3.2N・m | 3.2N・m |

| Allowable load moment | 4.5N・m | ||

| Ambient operating temperature and humidity | 0-40℃, 20-85% RH or less (no condensation) | ||

| Protection grade | IP20 | ||

| Vibration resistant/Shock resistant | No shock or vibration | ||

| Noise (Note 7) | 80dB or less | ||

| Compatible to overseas standards | CE mark, RoHS compliant | ||

| Motor type | AC servo motor | ||

| Motor capacity | 1st arm | 400W | |

| 2nd arm | 200W | ||

| Vertical axis | 100W | ||

| Rotating shaft | ― | 100W | |

| Encoder type | Battery-less absolute | ||

| Encoder pulse number | 16384 pulse/rev | ||

| Delivery | Written in [Reference for delivery] section of the homepage | ||

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network ※Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| XSEL-RAX/SAX |  | 8 | Three-phase AC200V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | - | - | - | 36666 (depending on type) |

(Note) Refer to page 7-17 for network abbreviation symbols such as DV and CC.

(Note) It can control up to SCARA + 4-axis robot.

Oversea specification

Important notes on selection

| (1) Refer to page 4-748 for (Note 1) to (Note 9). (2) The maximum set value of acceleration / deceleration changes depending on the mass of the object to be transported, the moving distance, and the location. An overload error may occur if continuous operation was performed with the maximum set value. When performing continuous operation, lower the acceleration / deceleration value or set a stop time after acceleration / deceleration with reference to the duty (based on the guideline). (3) Absolute reset is necessary whenever the motor is replaced. An adjustment jig is required for the absolute reset of the rotating shaft (4th shaft). Refer to page 4-742 for further details. (4) SCARA robots cannot operate continuously at 100% speed and acceleration. Refer to "Guidelines for acceleration / deceleration settings" for the operating condition. |

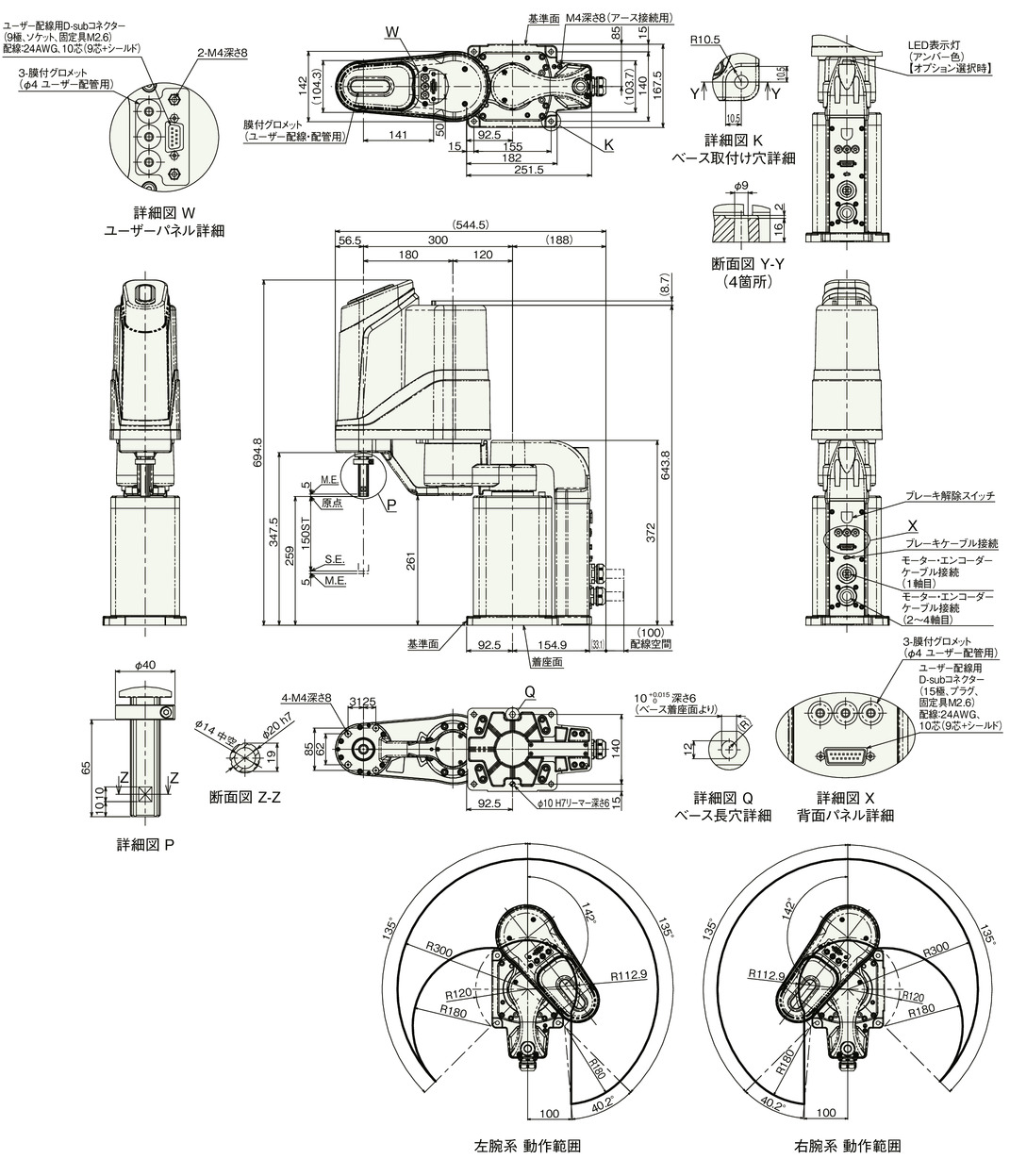

Dimension drawing

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

(Note) Refer to (Note 9) in page 4-748 for cable connection.

Mass

| Heading | Contents | |

|---|---|---|

| Mass | 3-axis type | 21kg |

| 4-axis type | 22kg | |

Cycle time

| Heading | Time |

|---|---|

| Standard Cycle Time | 0.38 sec |

| Continuous cycle time | 0.55 sec |

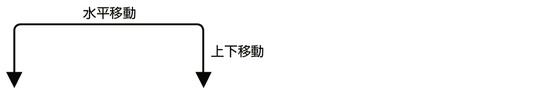

The standard / continuous cycle time indicates the time required when operating with the fastest round-trip operation setting under the following conditions.

Transfer mass of 2kg, vertical movement of 25mm and horizontal movement of 300mm (coarse positioning arch motion)

[Standard cycle time]

The time required for the fastest operation. Generally, this is a guide for high-speed performance. Please note that continuous operation at the fastest operation is not possible.

[Continuous cycle time]

The cycle time for continuous operation.

Allowable load moment of inertia at the tip shaft

| Number of axes | Allowable load moment of inertia at the tip shaft |

|---|---|

| 3-axis type | 0.06 kg・m2 |

| 4-axis type |

The allowable moment of inertia of 4th axis is the allowable moment of inertia converted to the center of rotation of the 4th axis (rotating shaft) of the SCARA robot. The offset amount from the center of rotation of the 4th axis to the center of gravity of the tool should be within the following values. If the position of the center of gravity of the tool deviates from the center position of the 4th axis, it is required to reduce the speed and acceleration as appropriate. The overhang length is limited based on the load and operating conditions.

| Horizontal direction | Vertical direction |

|---|---|

| 150mm or less | 100mm or less |

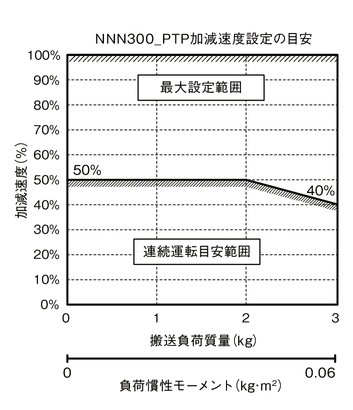

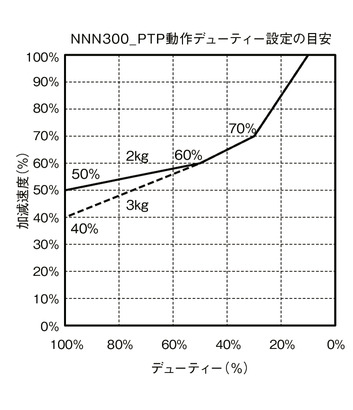

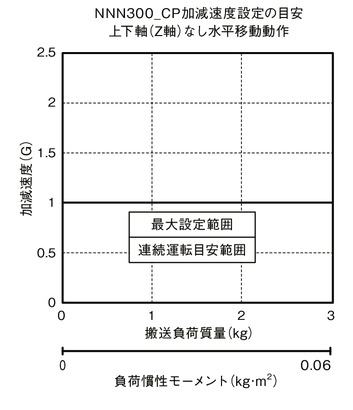

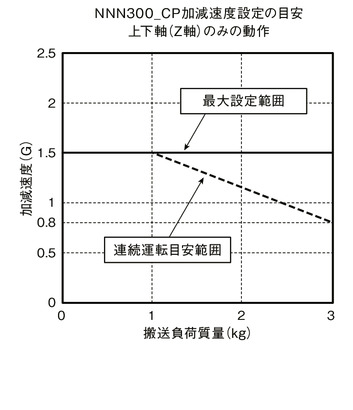

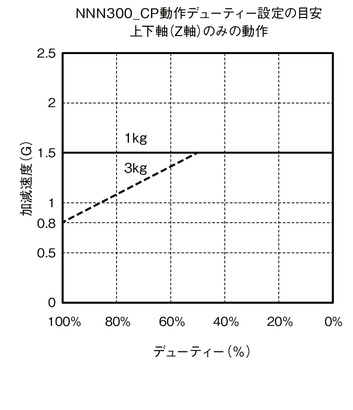

Guideline for acceleration / deceleration setting

SCARA Robot IXA cannot operate continuously at the maximum acceleration / deceleration and maximum speed noted in the catalog. When operating at the maximum acceleration / deceleration, set the stop time by referring to the guideline graph of continuous operation duty. If continuous operation is required, operate with the acceleration / deceleration setting within the continuous operation guideline range described in guideline graph for acceleration / deceleration setting.

(1) In case of PTP operation, be sure to use the WGHT instruction on the program to set the mass and moment of inertia before operating. For SCARA high speed compatible products,the maximum acceleration / deceleration that can operate at each transport mass is set as 100%. Please note that the operating time will be different if the transport mass is different even if the acceleration / deceleration and speed settings are the same.

(2) Adjust the acceleration / deceleration by gradually increasing the set value from the continuous operation guideline value.

(3) If an overload error occurs, reduce the acceleration / deceleration as appropriate, or make adjustments to set a stop time by referring to the guideline for continuous operation duty.

(4) Duty (%) = (Operating time / (Operating time + Stopping time)) x 100

(5) If you wish to move the robot horizontally at high speed, move the vertical axis as close to the rising end as possible.

(6) Keep the moment of inertia and the loaded mass below the allowable values.

(7) The transport load indicates the moment of inertia and mass of the center of rotation of the 4th axis.

(8) Operate the robot within the appropriate acceleration / deceleration according to the mass and moment of inertia of the 4-axis specification. Failure to do so will result in shortened life span, damage and vibration of the drive.

(9) If the moment of inertia of the load is large, vibration may occur at the vertical axis depending on its position. If vibration occurs, slow down the acceleration / deceleration as appropriate.

PTP operation

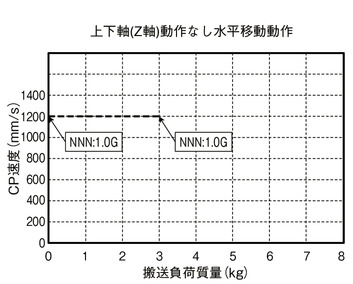

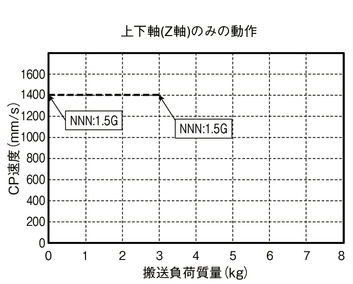

CP operation

Horizontal

Vertical

CP operation speed / acceleration / deceleration limit