(Note) The photograph shows the 4-axis specification.

Main specification

| Heading | Contents | |||

|---|---|---|---|---|

| 3-axis type | 4-axis type | |||

| Maximum load capacity (kg) (Note 1) | 6 | |||

| Speed (Note 2) | Maximum resultant speed (mm/s) | 2501 | ||

| Maximum speed of each axis | 1st arm (degree/s) | 153 | ||

| 2nd arm (degree/s) | 204 | |||

| Vertical axis (mm/s) | 240 | |||

| Rotating axis (degree/s) | - | 700 | ||

| Push force (N) | Upper limit | Unavailable | ||

| Minimum | Unavailable | |||

| Arm length (mm) | 550 | |||

| Arm length of each axis (mm) | 1st arm | 260 | ||

| 2nd arm | 290 | |||

| Operating range of each axis | 1st arm (degree) | ±127 | ||

| 2nd arm (degree) | ±127 | |||

| Vertical axis (mm) | 200 | |||

| Rotating axis (degree) | - | ±360 | ||

| Heading | Contents | ||

|---|---|---|---|

| 3-axis type | 4-axis type | ||

| Repeated positioning accuracy (Note 3) | Horizontal plane | ±0.040 mm | |

| Vertical axis | ±0.020 mm | ||

| Rotating shaft | ー | ±0.020 degree | |

| User wiring | Absent | ||

| User piping | Absent | ||

| Alarm indicator light | Absent | ||

| Brake release switch | Absent | ||

| Tip shaft | Allowable torque | 3.1 N・m | 3.1 N・m |

| Allowable load moment | 9.4 N・m | ||

| Main material | See page 1-345. | ||

| Ambient operating temperature and humidity | Temperature 0-40℃ Humidity 20-85% RH or less (no condensation) | ||

| Protection grade | IP65 (excl. bellows) | ||

| Air purge pressure (Note 4) | 1kPa | ||

| Vibration resistant/Shock resistant | No shock or vibration | ||

| Noise (Note 5) | 78dB or less | ||

| Compatible to overseas standards | ー | ||

| Motor type | Pulse motor | ||

| Motor capacity | 1st arm | ー | |

| 2nd arm | ー | ||

| Vertical axis | ー | ||

| Rotating shaft | ー | ー | |

| Encoder type | Battery-less absolute | ||

| Encoder pulse No. | 8192 pulse/rev | ||

| Delivery | Written in [Reference for delivery] section of the homepage | ||

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network *Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MSEL-PCX/PGX |  | 4 | Single phase AC 100 - 230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

(Note) Refer to page 8-17 for network abbreviations such as DV and CC.

Important notes on selection

| (1) For (Note 1) to (Note 5) refer to page 7-677. (2) Please select the brake option if the handled load weighs 4 kg or more. (3) Vertical axis does not support push control. (4) The allowable pressing force will be 90N when a buffer (e.g. spring) is provided on the tool or pressing side. (5) When switching the arm system, the arm will once extend in a straight line, so be careful of interference with peripheral devices. (6) Flange option is available. Refer to page 7-692 for further details. |

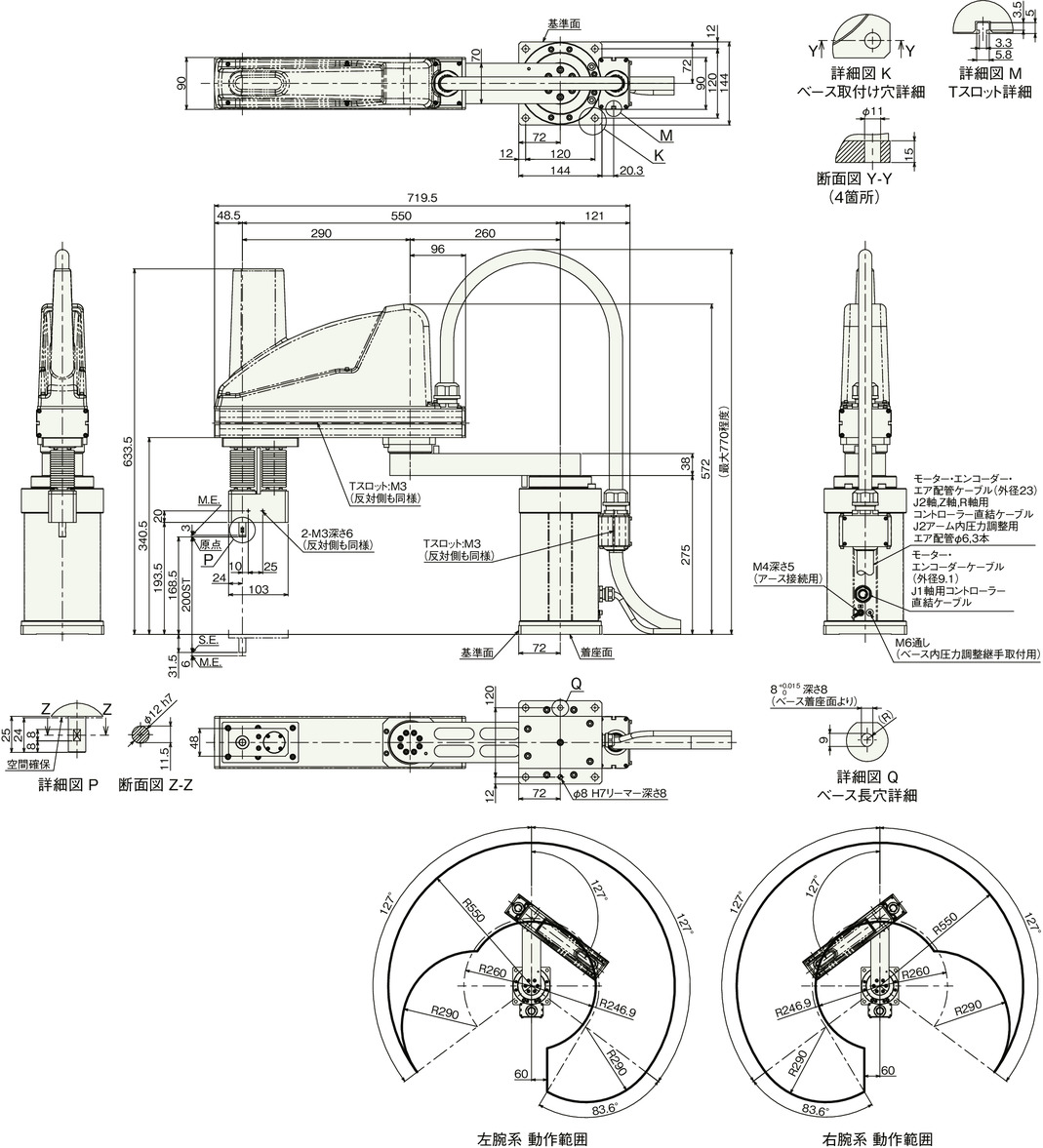

Dimension drawing

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

Mass

| Heading | Contents | |

|---|---|---|

| Mass | 3-axis type | 25.0kg |

| 4-axis type | 27.0kg | |

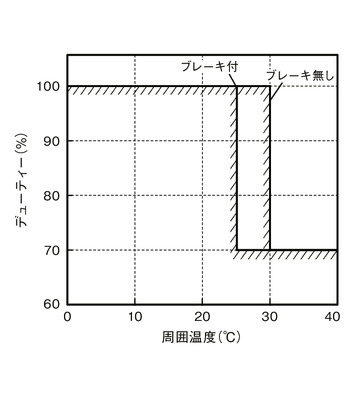

Duty cycle setting

The duty cycle is the operating rate in percentage (%) of the time the robot is operating during one cycle. This robot has a duty cycle limit based on ambient temperature to suppress the heat generation of the motor unit and reducing gear. Operate both PTP and CP operation within the values in the graph below. Do not run a continuous operation for more than 30 minutes.

(1) Operate with duty cycle within the upper limit for this may shorten the service life of the motor unit and the reducing gear.

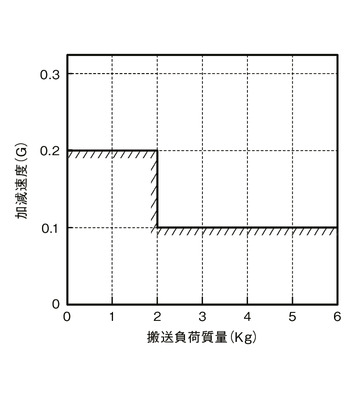

Guideline for acceleration / deceleration setting

If continuous operation is required, operate within the range of the graph for acceleration / deceleration setting and duty cycle setting guideline.

PTP operation

For speed and acceleration / deceleration, the operable value when the transport load is taken into consideration is set as 100% (optimal speed / optimum acceleration / deceleration feature). Adjust to the desired speed and acceleration / deceleration.

(1) Optimal speed / optimum acceleration / deceleration feature does not provide guarantee for it to operate in all operation patterns.

(2) Slow down the speed or acceleration / deceleration as appropriate if significant vibration occurs, for it may cause a malfunction or may shorten its service life.

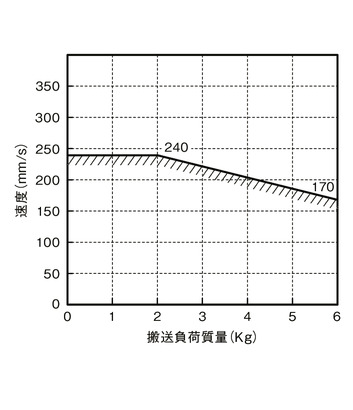

CP operation

Set the speed and acceleration / deceleration up to the values in the graph below.

(1) Slow down the speed or acceleration / deceleration as appropriate if significant vibration occurs, for it may cause a malfunction or may shorten its service life.

Cycle time

| Heading | Time |

|---|---|

| Standard Cycle Time | 0.79 sec |

| Continuous cycle time | 0.79 sec |

The standard / continuous cycle time indicates the time required when operating with the fastest round-trip operation setting under the following conditions.

Transfer mass of 2kg, vertical movement of 25mm and horizontal movement of 300mm (coarse positioning arch motion)

[Standard cycle time]

The time required for the fastest operation. Generally, this is a guide for high-speed performance.

[Continuous cycle time]

The cycle time for continuous operation.

Allowable load moment of inertia at the tip shaft

| Number of axes | Allowable load moment of inertia at the tip shaft |

|---|---|

| 3-axis type | 0.03 kg・m2 |

| 4-axis type | 0.01 kg・m2 |

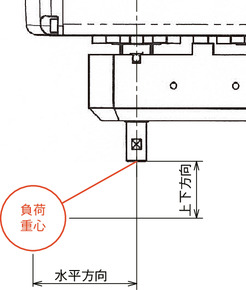

The allowable load moment of inertia of the tip axis is the allowable moment of inertia when the tip spline axis of the SCARA robot is converted to the center. The offset amount from the tip axis to the load center should be within the following values. If the position of the center of gravity of the load deviates from the tip axis, it is required to reduce the speed and acceleration as appropriate.

| Horizontal direction | Vertical direction |

|---|---|

| 30mm or less | 100mm or less |