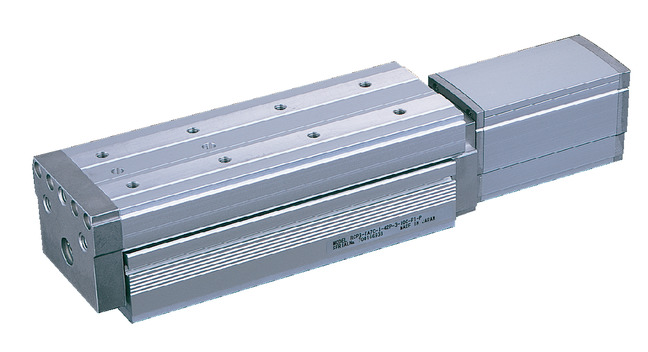

Actuator specification

| Model | Motor output (W) | Lead (mm) | Maximum Load Capacity | Rated thrust (N) | Stroke (mm) | |

|---|---|---|---|---|---|---|

| Horizontal (kg) | Vertical (kg) | |||||

| RCA2-TA7C-I-30-12-①-②-③-④ | 30 | 12 | 4 | 1 | 26 | 25 - 200 (In increments of 25mm) |

| RCA2-TA7C-I-30-6-①-②-③-④ | 6 | 6 | 2.5 | 53 | ||

| RCA2-TA7C-I-30-3-①-②-③-④ | 3 | 8 | 4 | 105 | ||

Symbol description ① Stroke ② Adaptive controller ③ Cable length ④ Option

| Stroke lead | 25 - 200 (In increments of 25mm) |

|---|---|

| 12 | 600<580> |

| 6 | 300 |

| 3 | 150 |

(Measured in mm/s)

(Note) The value within < > are applicable for those installed vertically.

Actuator specification

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ10mm, rolled C10 |

| Accuracy of Repeating Positioning. | ±0.02mm |

| Lost motion | 0.1mm and below |

| Base | Base: Aluminum, with white alumite treatment |

| Allowable static moment value | Ma:42.6N・m Mb:60.8N・m Mc:123.2N・m |

| Allowable dynamic moment (Note1) | Ma:11.6N・m Mb:16.6N・m Mc:33.7N・m |

| Ambient operating temperature and humidity | 0 - 40℃, 85% RH and below (Non-condensing) |

(Note1) Values shown are for basic rated life of 5,000km. Life time travelling distance differs based on operating condition and attached condition.

Please refer to page 1-342 for life time travelling distance.

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network ※Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| ACON-CB/CGB |  | 1 | DC24V | ● ※Selectable | ● ※Selectable | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) |

| ACON-CYB/PLB/POB |  | 1 | ● ※Selectable | ● ※Selectable | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| ASEL-CS |  | 2 | ● | - | ● | ● | ● | - | ● | - | - | - | - | ● | - | - | - | 1500 | |

| MCON-C/CG |  | 8 | - | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | ● | ● | ● | 256 | |

| MCON-LC/LCG |  | 6 | - | - | ● | ● | ● | - | ● | ● | - | - | ● | ● | ● | - | - | 256 | |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

(Note) Please refer page 7-15 for network abbreviations such as DV and CC.

Oversea specification

Feature

Important notes on selection

| (1) Take note that the maximum speed for horizontal use differs from of vertical use. (2) Load capacity assumes an acceleration of 0.3G (0.2G for lead 3 and vertical operation), which is its upper limit for acceleration. (3) Available duty depends on the operating condition (e.g.load mass, acceleration/deceleration). Refer page 1-452 for further information. (4) Encoder type box for model item will be "I" for simple absolute as well. (5) Overhang load length has to be within the range of allowable dynamic moment. (6) Precaution is required depending on the attachment orientation. Please refer to page 1-361 for further details. |

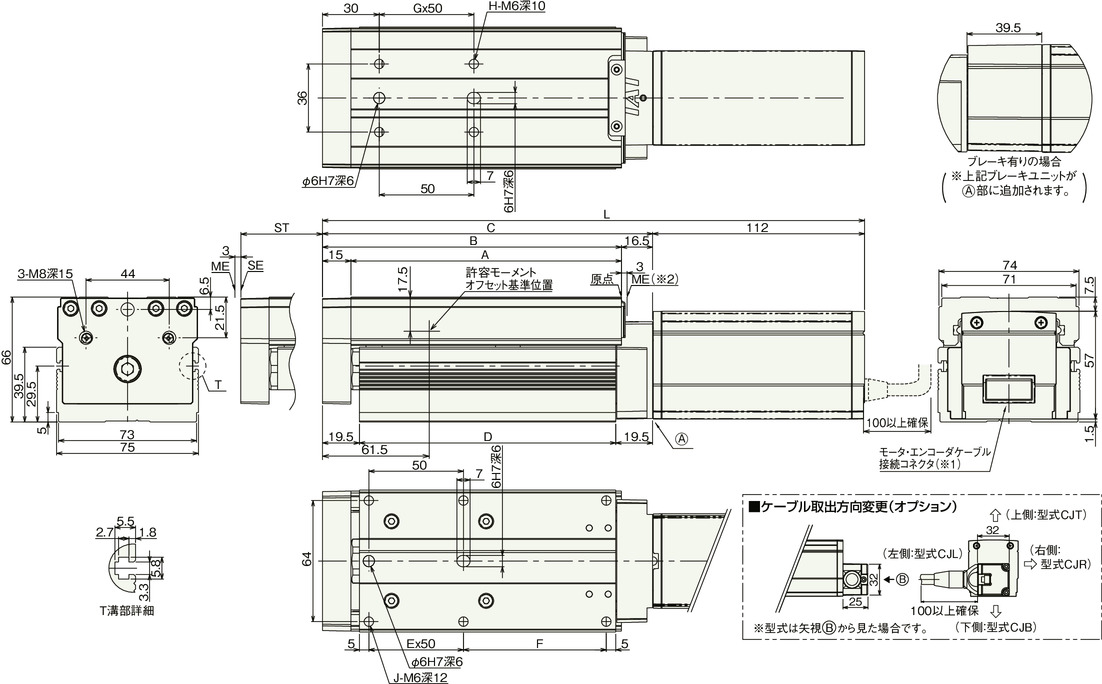

Dimension drawing

ST: Stroke

ME: Mechanical end

SE: Stroke end

※1 Connect a motor/encoder cable (integrated model). Refer page 1-255 for further information on the cable.

※2 Ensure the slider does not collide with other items, for it will return to ME after homing process.

Dimension/Mass by stroke

| Stroke | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | |

|---|---|---|---|---|---|---|---|---|---|

| L | Brake present | 261.5 | 286.5 | 311.5 | 336.5 | 361.5 | 386.5 | 411.5 | 436.5 |

| Brake absent | 301 | 326 | 351 | 376 | 401 | 426 | 451 | 476 | |

| A | 118 | 143 | 168 | 193 | 218 | 243 | 268 | 293 | |

| B | 133 | 158 | 183 | 208 | 233 | 258 | 283 | 308 | |

| C | 149.5 | 174.5 | 199.5 | 224.5 | 249.5 | 274.5 | 299.5 | 324.5 | |

| D | 110.5 | 135.5 | 160.5 | 185.5 | 210.5 | 235.5 | 260.5 | 285.5 | |

| E | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | |

| F | 50.5 | 75.5 | 50.5 | 75.5 | 50.5 | 75.5 | 50.5 | 75.5 | |

| G | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | |

| H | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | |

| J | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | |

| Mass (kg) | 2.1 | 2.3 | 2.5 | 2.8 | 3 | 3.2 | 3.4 | 3.6 | |

(Note) There will be an additional mass of 0.4kg for specification with brake.