Main specification

| Heading | Contents | |

|---|---|---|

| Speed reduction | 1/30 | |

| Gripping Motion | Max. Gripping Force (N)(Both sides) | 60 |

| Max. speed of gripping motion (degree/s)(per side) | 20 | |

| Approaching Motion | Max. speed (degree/s)(per side) | 600 |

| Min. speed (degree/s)(per side) | 20 | |

| Rated Acceleration/Deceleration (G)(Per side) | 0.3 | |

| Max. Acceleration/Deceleration (G)(Per side) | 0.3 | |

| Stroke (Per side) | Min. stroke (degree)(per side) | 90 |

| Max. stroke (degree)(per side) | 90 | |

| Heading | Contents |

|---|---|

| Drive system | Worm gear + Helical gear |

| Accuracy of Repeating Positioning. | ±0.05 degree |

| Homing precision | 1 degree or less |

| Backlash | 2.5 degrees or less per side(Always pressured to open side via spring) |

| Lost motion | 0.3 degree or less per side |

| Allowable thrust load (Vertical payload) | 73.5N |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) |

| Protection grade | - |

| Vibration resistant/Shock resistant | 4.9m/s2 |

| Compatible to overseas standards | CE mark, RoHS compliant |

| Motor type | Pulse motor |

| Encoder type | Incremental |

| Encoder pulse No. | 800 pulse/rev |

| Delivery | Written in [Reference for delivery] section of the homepage |

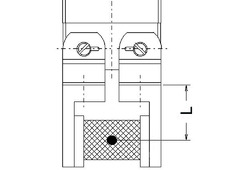

Checking the Gripping Point Distance

When using, please use with a gripping point distance (L) of 100mm or less.

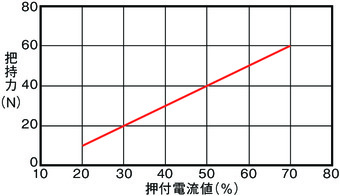

Correlation Diagram of Gripping Force and Current Limit Value

(Note) This is the gripping force on the upper surface of the lever. The actual gripping force decreases in inverse proportion to the distance from the opening/closing fulcrum. The effective gripping force can be calculated from the following formula.

Effective gripping force (GRLL) = F x 26/(L + 26)

(Note) Gripping force is the total value of both fingers.

(Note) Values indicated are for reference only. There is a maximum variation of about ± 15%.

(Note) The speed is fixed at 20 degrees/s for gripping (pushing) motion.

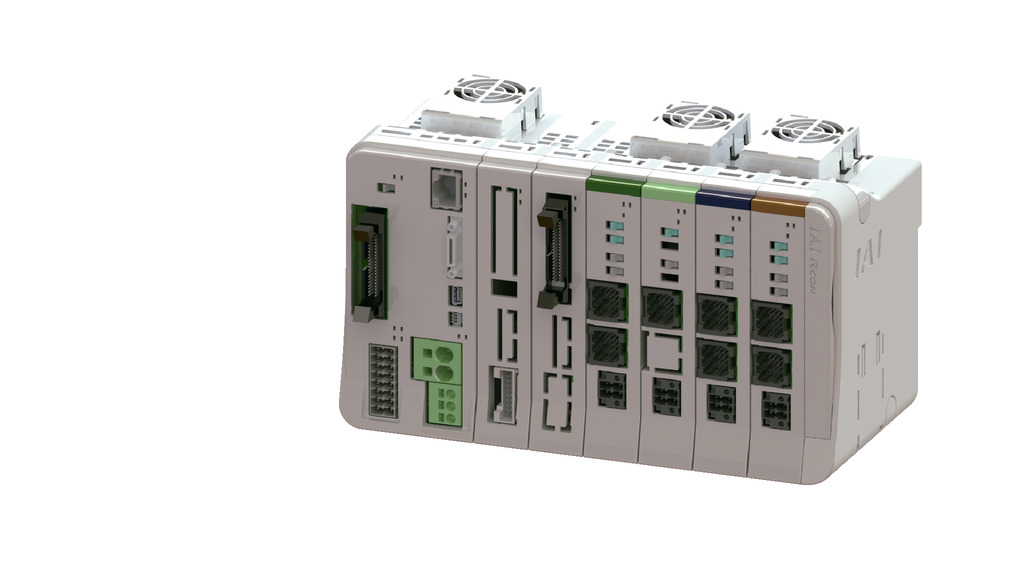

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network *Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MCON-C/CG |  | 8 | DC24V | - | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | ● | ● | ● | 256 |

| MSEL-PC/PG |  | 4 | Single phase AC 100 - 230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CB/CGB |  | 1 | DC24V | ● *Selectable | ● *Selectable | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) |

| PCON-CYB/PLB/POB |  | 1 | ● *Selectable | ● *Selectable | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

| RSEL |  | 8 | - | - | ● | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 36000 | |

(Note) Refer to page 7-17 for network abbreviations such as DV and CC.

Oversea specification

Important notes on selection

| (1) The maximum opening/closing speed of the "Main specification" indicates the operating speed of one side. The relative operating speed is twice this value. (2) The maximum gripping force of the "Main specification" is the total value of the gripping force of both fingers when the gripping point distance and the overhang distance is 0. For the mass of the work that can be actually transported, refer to "Correlation diagram between gripping force and current limit value". (3) Be sure to use push-motion operation to grip the work. Refer to page 1-317 for further details. (4) Encoder type box for model item will be "I" for simple absolute as well. (5) Safety measures may be required depending on the attachment orientation. Refer to page 1-199 for further details. (6) The high output setting of the controller is can only be set to invalid. |

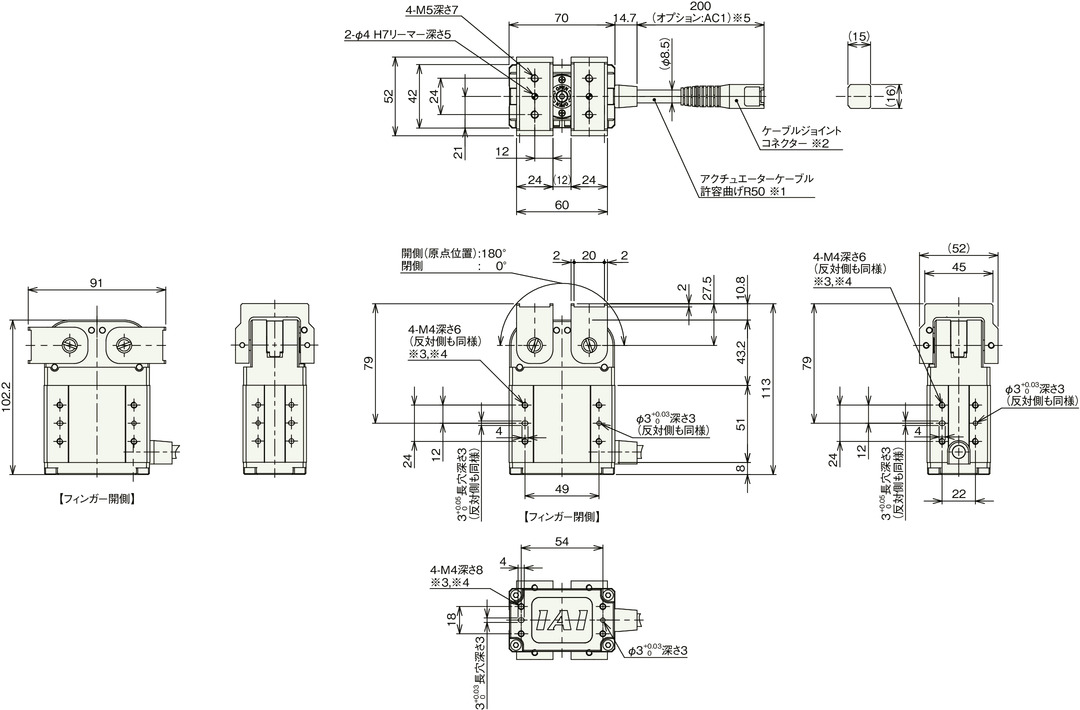

Dimension drawing

※1 The actuator cable is a robot cable.

※2 To be connected to motor/encoder cable.

※3 When fixing the main body, use all the taps (4 places) on the same mounting surface to fix.

※4 Do not screw in the bolt beyond the depth of the fixing tap. It may damage the internal parts.

※5 The standard cable length is 200mm, and it can be changed to 1000mm by specifying the option (model: AC1).

(Note) The open side is set as the home position as standard, and it can be changed to closed side by specifying the option (model: NM).

Mass

| Heading | Contents |

|---|---|

| Mass | 1.0kg |