Actuator specification

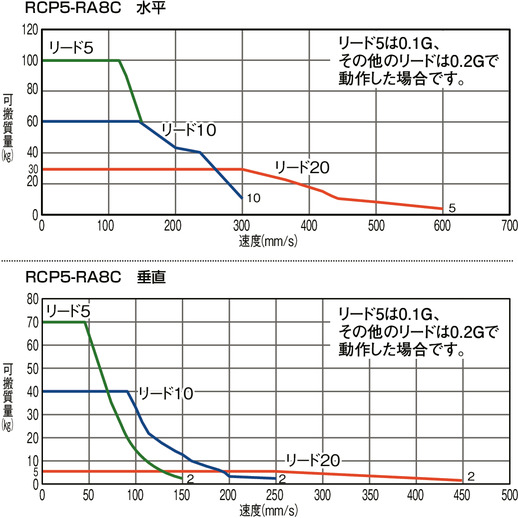

| Model | Lead (mm) | Maximum Load Capacity | Maximum pressing force (N) | Stroke (mm) | |

|---|---|---|---|---|---|

| Horizontal (kg) | Vertical (kg) | ||||

| RCP5-RA8C-WA-60P-20-①-P4-②-③ | 20 | 30 | 5 | 500 | 50 - 700 (50mm intervals) |

| RCP5-RA8C-WA-60P-10-①-P4-②-③ | 10 | 60 | 40 | 1000 | |

| RCP5-RA8C-WA-60P-5-①-P4-②-③ | 5 | 100 | 70 | 2000 | |

Symbol description ① Stroke ② Cable length ③ Option

| Lead (mm) | 50 (mm) | 100 (mm) | 150 (mm) | 200 (mm) | 250~350 (mm) | 400 (mm) | 450 (mm) | 500 (mm) | 550 (mm) | 600 (mm) | 650 (mm) | 700 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 280 | 405 | 505 <450> | 585 <450> | 600 <450> | 520 <450> | 440 | 360 | 320 | 280 | 240 | 220 |

| 10 | 280 <250> | 300 <250> | 260 <250> | 220 | 180 | 160 | 140 | 120 | 110 | |||

| 5 | 150 | 130 | 110 | 90 | 80 | 70 | 60 | 55 | ||||

(Measured in mm/s)

(Note) The value within < > are applicable for those installed vertically.

Correlation diagram of speed and load capacity

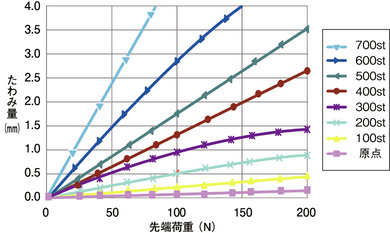

Flexible volume (reference value)

Diagram below shows the flexible volume of a rod tip when a force is applied to the tip upon setting the actuator in horizontal posture (includes flexure due to the weight of the rod)

Actuator specification

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ16mm, rolled C10 |

| Accuracy of Repeating Positioning. | ±0.02mm |

| Lost motion | 0.1mm and below |

| Rod | φ40mm Aluminum |

| Non-rotational accuracy of rod (Note1) | 0° |

| Allowable load / torque at the rod tip | Refer dimension by stroke table, or page 1-475 of the General Catalogue 2017 |

| Rod tip overhanging distance | 100mm and below |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (Non-condensing) |

(Note1) Displacement angle of the rotating direction of the rod when there is no load applied.

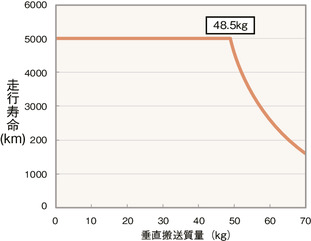

Correlation of vertical load capacity and lifetime travelling distance

Usage of lead 5 in vertical manner may cause life span to be affected by the load capacity. Kindly take note on the life span and the load capacity as shown in the graph below (No effect shall take place due to load capacity if set in horizontal posture)

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network ※Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MSEL-PCF/PGF |  | 4 | Single phase AC 100 - 230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CFB/CGFB (60P motor compatible type) |  | 1 | DC24V | ● ※Selectable | ● ※Selectable | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

(Note) Please refer to page 6 -13 for abbreviated names of network (e.g. DV, CC).

(Note) The product can't be connected to the 3rd and 4th axis of MSEL-PCF/PGF.

Oversea specification

Feature

Important notes on selection

| (1) Load capacity shown in "Actuator specification" refers to its maximum value, for the actual value changes based on its acceleration. Refer "Load capacity by speed/acceleration / RCP5 series" on page 1-493 for further information. (2) Please refer to page 1-387 of general catalogue 2017 for pressing motion. (3) Radial cylinder comes with a built-in guide. Refer the graph on page 1-475 of the General Catalogue 2017 for load mass allowable. (4) Safety measures may be required based on mounting orientation. Please refer to page 1-379 for further information. (5) Conversion unit or cable is needed to connect RCON. Please refer to page Home for further details. |

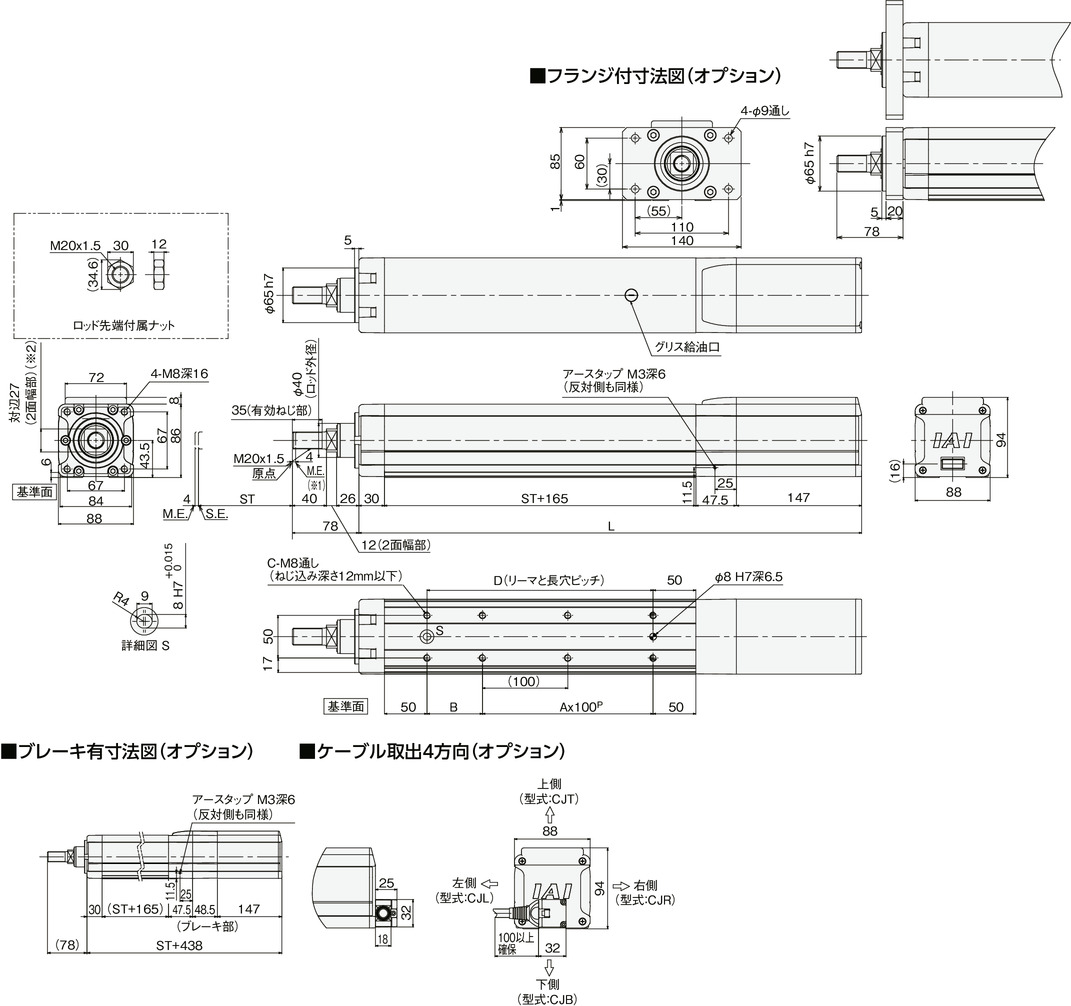

Dimension drawing

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

*1 The rod moves to the M.E. upon returning to origin, so please take precaution that it may not interfere with anything while the returning process is running.

*2 The direction the width between two flats are facing differs by product.

*3 Be sure that no external force is applied on to the main body if it is attached using a front bracket.

Dimension/Mass by stroke

| Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | Brake present | 439.5 | 489.5 | 539.5 | 589.5 | 639.5 | 689.5 | 739.5 | 789.5 | 839.5 | 889.5 | 939.5 | 989.5 | 1039.5 | 1089.5 |

| Brake absent | 488 | 538 | 588 | 638 | 688 | 738 | 788 | 838 | 888 | 938 | 988 | 1038 | 1088 | 1138 | |

| A | 0 | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | |

| B | 115 | 65 | 115 | 65 | 115 | 65 | 115 | 65 | 115 | 65 | 115 | 65 | 115 | 65 | |

| C | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | |

| D | 115 | 165 | 215 | 265 | 315 | 365 | 415 | 465 | 515 | 565 | 615 | 665 | 715 | 765 | |

| Allowable static load at the rod tip (N) | 180 | 150.3 | 128.9 | 112.7 | 99.9 | 89.7 | 81.3 | 74.3 | 68.3 | 63.1 | 58.6 | 54.6 | 51.1 | 47.9 | |

| Allowable dynamic load on the rod tip (N) | Load off-set 0mm | 73.6 | 60.3 | 51.0 | 44.1 | 38.7 | 34.3 | 30.7 | 27.7 | 25.2 | 23.0 | 21.1 | 19.4 | 17.8 | 16.5 |

| Load off-set 100mm | 57.0 | 48.6 | 42.5 | 37.8 | 33.8 | 30.5 | 27.6 | 25.2 | 23.1 | 21.2 | 19.5 | 18.1 | 16.7 | 15.5 | |

| Allowable static torque at the rod tip (Nm) | 18.1 | 15.2 | 13.0 | 11.4 | 10.2 | 9.2 | 8.4 | 7.7 | 7.1 | 6.6 | 6.1 | 5.8 | 5.4 | 5.1 | |

| Allowable dynamic torque at the rod tip (N・m) | 5.7 | 4.9 | 4.3 | 3.8 | 3.4 | 3.0 | 2.8 | 2.5 | 2.3 | 2.1 | 2.0 | 1.8 | 1.7 | 1.5 | |

| Mass (kg) | Brake present | 7.1 | 7.6 | 8.0 | 8.4 | 8.9 | 9.3 | 9.7 | 10.2 | 10.6 | 11.0 | 11.4 | 11.9 | 12.3 | 12.7 |

| Brake absent | 8.3 | 8.7 | 9.1 | 9.6 | 10.0 | 10.4 | 10.9 | 11.3 | 11.7 | 12.1 | 12.6 | 13.0 | 13.4 | 13.9 | |