メインスペック

| 項目 | 内容 | ||

|---|---|---|---|

| リード | 送りねじリード(mm) | 8 | 2 |

| 把持動作 | 最大把持力(N)(両側) | 110 | 310 |

| 把持動作時の最高速度(mm/s)(片側) | 10 | 5 | |

| アプローチ動作 | 最高速度(mm/s)(片側) | 180 | 45 |

| 最低速度(mm/s)(片側) | 10 | 5 | |

| 定格加減速度(G)(片側) | 0.3 | 0.3 | |

| 最高加減速度(G)(片側) | 0.3 | 0.3 | |

| ブレーキ | ブレーキ仕様 | 無励磁作動電磁ブレーキ | |

| ブレーキ保持力(kgf) | 5.5 | 15.5 | |

| ストローク(片側) | 最小ストローク(mm)(片側) | 90 | 90 |

| 最大ストローク(mm)(片側) | 115 | 115 | |

| 項目 | 内容 |

|---|---|

| 駆動方式 | タイミングベルト+左右台形ねじ |

| 繰返し位置決め精度 | ±0.01mm |

| バックラッシ | リード8mm:片側0.3mm以下、リード2mm:片側0.25mm以下 |

| ロストモーション | リード8mm:片側0.3mm以下、リード2mm:片側0.25mm以下 |

| ベース | 材質:アルミ、白色アルマイト処理 |

| リニアガイド | 直動無限循環型 |

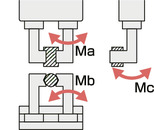

| 静的許容モーメント | Ma:48N・m |

| Mb:69N・m | |

| Mc:103N・m | |

| 動的許容モーメント (注2) | Ma:11N・m |

| Mb:16N・m | |

| Mc:24N・m | |

| 許容スラスト荷重(垂直方向許容荷重) | 1080N |

| 使用周囲温度・湿度 | 0~40℃、85%RH以下(結露なきこと) |

| 保護等級 | IP20 |

| 耐振動・耐衝撃 | 4.9m/s2 |

| 海外対応規格 | CEマーク、RoHS指令 |

| モーター種類 | パルスモーター |

| エンコーダー種類 | バッテリーレスアブソリュート |

| エンコーダーパルス数 | 8192 pulse/rev |

| 納期 | ホームページ[納期照会]に記載 |

(注2) 基準定格寿命5,000kmの場合です。走行寿命は運転条件、取付け状態によって異なります。

1-180にて走行寿命をご確認ください。

スライドタイプモーメント方向

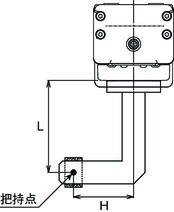

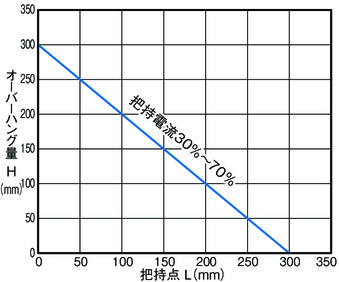

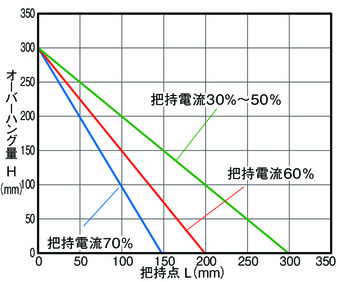

把持点距離の確認

フィンガー(爪)取付け面から把持点までの距離(L、H)をグラフの範囲内となるようにご使用ください。

(注) 制限範囲を超えた場合はフィンガー摺動部および内部メカに過大なモーメントが作用して、寿命に悪影響を及ぼす原因となります。

リード8

リード2

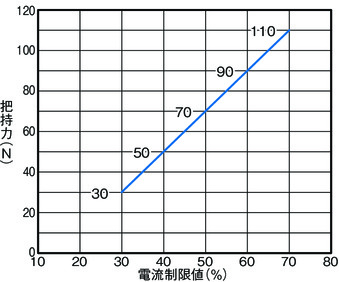

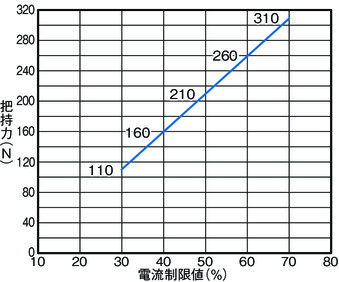

把持力と電流制限値の相関図

リード8

(注) グラフの把持力は把持点距離(L、H)が0の場合となり、両フィンガーの合計値です。

リード2

適応コントローラー

本ページのアクチュエーターは下記のコントローラーで動作が可能です。ご使用になる用途に応じたタイプをご選択ください。

| 名称 | 外観 | 最大接続 可能軸数 | 電源電圧 | 制御方法 | 最大位置決め点数 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ポジショナー | パルス列 | プログラム | ネットワーク ※選択 | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MCON-C/CG |  | 8 | DC24V | - | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | ● | ● | ● | 256 |

| MSEL-PC/PG |  | 4 | 単相AC 100~230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CB/CGB |  | 1 | DC24V | ● ※選択 | ● ※選択 | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (ネットワーク仕様は768) |

| PCON-CYB/PLB/POB |  | 1 | ● ※選択 | ● ※選択 | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

| RSEL |  | 8 | - | - | ● | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 36000 | |

(注) DV、CCなどのネットワーク略称記号については、7-17ページをご確認ください。

(注) RCP6Sシリーズの内蔵コントローラーは、7-103ページをご確認ください。

選定上の注意

| (1)「メインスペック」の開閉最高速度は片側の動作速度を表します。相対動作速度はこの値の2倍になります。 (2)「メインスペック」の最大把持力はスライダー上面(把持位置0㎜、オーバーハング量0㎜)の場合の両スライダー把持力の合計値です。 (3)「把持力と電流制限値の相関図」のバラツキは±25%(F.S.)(目安)です。 (4)張出し負荷長の目安は、Ma・Mb・Mc方向 300㎜以下です。張出し負荷長は1-16ページの図をご確認ください。 (5)リード2はセルフロックにより、サーボOFFやコントローラー電源遮断時においてもワーク把持力を維持します。リード8はセルフロックがありません。 (6)コントローラーの高出力設定は無効のみです。 |

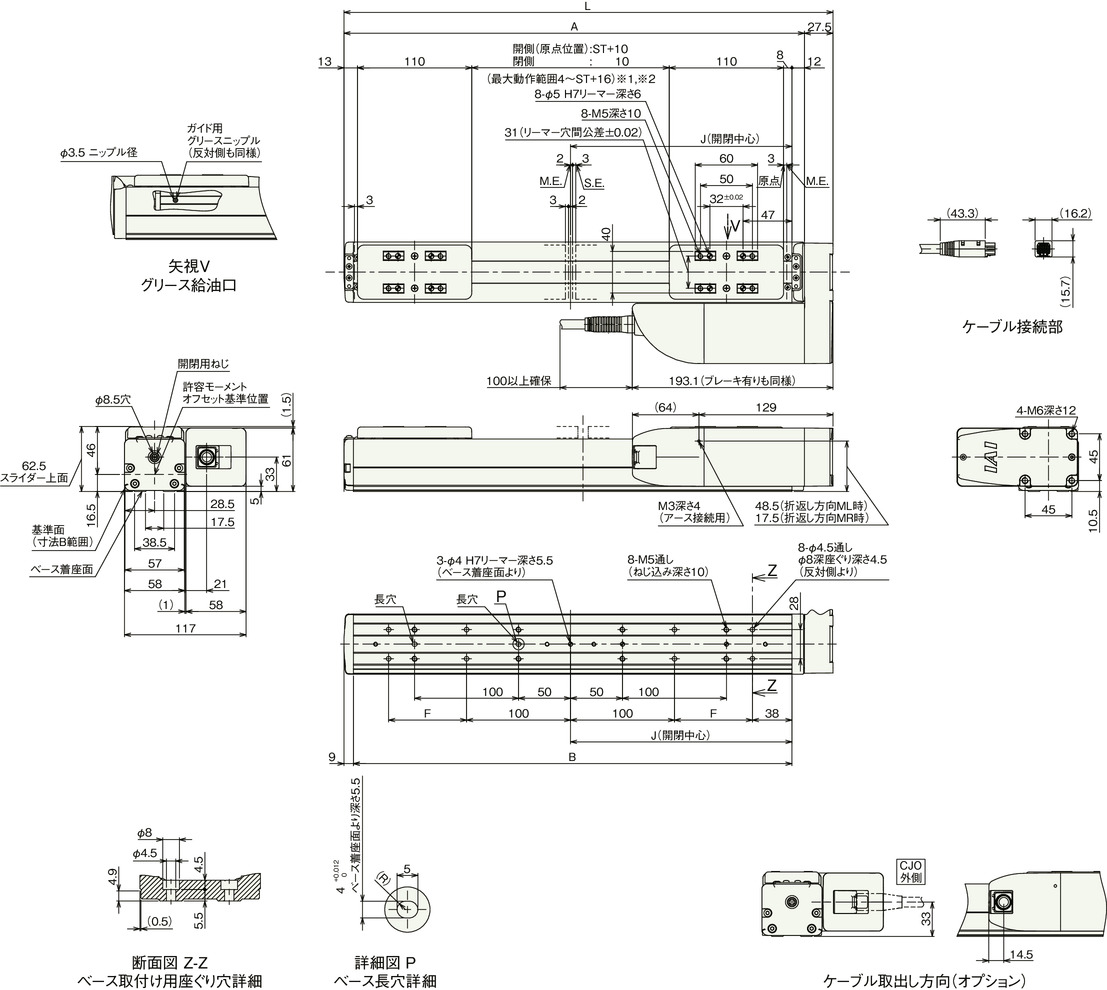

寸法図

RCP6-GRST6R

ST:開閉ストローク

M.E.:メカニカルエンド

S.E.:ストロークエンド

※1 原点復帰を行った場合は両スライダーがM.E.まで移動しますので周囲物との干渉にご注意ください。

※2 両スライダーは同時に反対方向に動作します。

(注) 座ぐり穴を使用して本体を固定する場合はモーターカバーを取外してからサイドカバーを取外してください。

(注) 下図はモーター左折返し仕様 (ML)の場合です。

ストローク別寸法

| ストローク | 180 | 230 | |

|---|---|---|---|

| L | ブレーキ無し | 470.5 | 520.5 |

| ブレーキ有り | |||

| A | 443 | 493 | |

| B | 422 | 472 | |

| F | 75 | 100 | |

| J | 213 | 238 | |

ストローク別質量

| ストローク | 180 | 230 | |

|---|---|---|---|

| 質量 (kg) | ブレーキ無し | 3.5 | 3.6 |

| ブレーキ有り | 3.5 | 3.7 | |

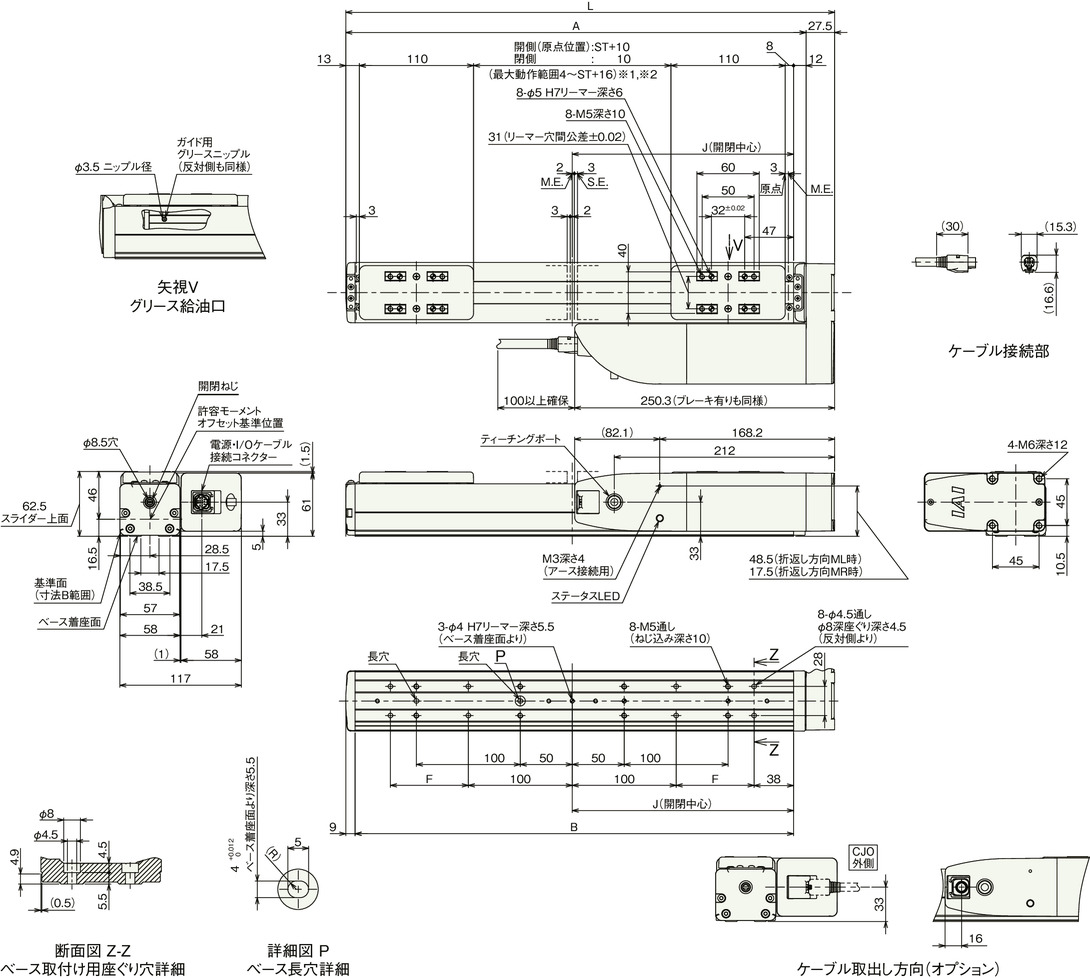

RCP6S-GRST6R

ST:開閉ストローク

M.E.:メカニカルエンド

S.E.:ストロークエンド

※1 原点復帰を行った場合は両スライダーがM.E.まで移動しますので周囲物との干渉にご注意ください。

※2 両スライダーは同時に反対方向に動作します。

(注) 座ぐり穴を使用して本体を固定する場合はモーターカバーを取外してからサイドカバーを取外してください。

(注) 下図はモーター左折返し仕様 (ML)の場合です。

ストローク別寸法

| ストローク | 180 | 230 | |

|---|---|---|---|

| L | ブレーキ無し | 470.5 | 520.5 |

| ブレーキ有り | |||

| A | 443 | 493 | |

| B | 422 | 472 | |

| F | 75 | 100 | |

| J | 213 | 238 | |

ストローク別質量

| ストローク | 180 | 230 | |

|---|---|---|---|

| 質量 (kg) | ブレーキ無し | 3.6 | 3.8 |

| ブレーキ有り | 3.7 | 3.8 | |