メインスペック

| 項目 | 内容 | ||||

|---|---|---|---|---|---|

| リード | ボールねじリード(mm) | 16 | 8 | 4 | |

| 水平 | 可搬質量 | 最大可搬質量(kg)(高出力有効) | 25 | 30 | 30 |

| 最大可搬質量(kg)(高出力無効) | 22 | 30 | 30 | ||

| 速度/加減速度 | 最高速度(mm/s) | 700 | 420 | 210 | |

| 最低速度(mm/s) | 20 | 10 | 5 | ||

| 定格加減速度(G) | 0.3 | 0.3 | 0.3 | ||

| 最高加減速度(G) | 1 | 1 | 1 | ||

| 垂直 | 可搬質量 | 最大可搬質量(kg)(高出力有効) | 7 | 16 | 24 |

| 最大可搬質量(kg)(高出力無効) | 5 | 12 | 20 | ||

| 速度/加減速度 | 最高速度(mm/s) | 560 | 350 | 210 | |

| 最低速度(mm/s) | 20 | 10 | 5 | ||

| 定格加減速度(G) | 0.5 | 0.3 | 0.5 | ||

| 最高加減速度(G) | 0.5 | 0.5 | 0.5 | ||

| 押付け | 押付け時最大推力(N) | 209 | 418 | 836 | |

| 押付け最高速度(mm/s) | 20 | 20 | 20 | ||

| ブレーキ | ブレーキ仕様 | 無励磁作動電磁ブレーキ | |||

| ブレーキ保持力(kgf) | 7 | 16 | 24 | ||

| ストローク | 最小ストローク(mm) | 40 | 40 | 40 | |

| 最大ストローク(mm) | 390 | 390 | 390 | ||

| ストロークピッチ(mm)(注1) | 50 | 50 | 50 | ||

(注1) ストローク40~90の間のみ25間隔です。

| 項目 | 内容 |

|---|---|

| 駆動方式 | ボールねじ φ12mm 転造C10 |

| 繰返し位置決め精度 | ±0.01mm |

| ロストモーション | 0.1mm以下 |

| ベース | 材質:アルミ 白色アルマイト処理 |

| リニアガイド | 直動無限循環型 |

| 静的許容モーメント | Ma:620N・m |

| Mb:620N・m | |

| Mc:458N・m | |

| 動的許容モーメント (注2) | Ma:196N・m |

| Mb:196N・m | |

| Mc:145N・m | |

| 使用周囲温度・湿度 | 0~40℃、85%RH以下(結露なきこと) |

| 保護等級 | - |

| 耐振動・耐衝撃 | 4.9m/s2 |

| 海外対応規格 | CEマーク、RoHS指令 |

| モーター種類 | パルスモーター |

| エンコーダー種類 | バッテリーレスアブソリュート |

| エンコーダーパルス数 | 8192 pulse/rev |

| 納期 | ホームページ[納期照会]に記載 |

(注2) 基準定格寿命5,000kmの場合です。走行寿命は運転条件、取付け状態によって異なります。1-180ページにて走行寿命をご確認ください。

テーブルタイプモーメント方向

速度・加速度別可搬質量表

高出力設定有効 可搬質量の単位はkgです。空欄は動作不可となります。

| 姿勢 | 水平 | 垂直 | ||||||

|---|---|---|---|---|---|---|---|---|

| 速度 | 加速度(G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 25 | 25 | 20 | 20 | 18 | 7 | 7 | 7 |

| 140 | 25 | 25 | 20 | 20 | 18 | 7 | 7 | 7 |

| 280 | 22 | 20 | 16 | 16 | 14 | 7 | 7 | 6 |

| 420 | 20 | 16 | 14 | 12 | 8 | 6 | 5 | 4 |

| 560 | 16 | 14 | 10 | 6 | 4 | 3 | 1.5 | 0.5 |

| 700 | 8 | 3.5 | ||||||

| 姿勢 | 水平 | 垂直 | ||||||

|---|---|---|---|---|---|---|---|---|

| 速度 | 加速度(G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 30 | 30 | 28 | 26 | 24 | 16 | 16 | 14 |

| 70 | 30 | 30 | 28 | 26 | 24 | 16 | 16 | 14 |

| 140 | 30 | 28 | 24 | 22 | 20 | 16 | 14 | 10 |

| 210 | 30 | 22 | 20 | 18 | 16 | 12 | 10 | 8 |

| 280 | 20 | 18 | 16 | 12 | 10 | 9 | 8 | 6 |

| 350 | 14 | 12 | 7 | 4 | ||||

| 420 | 8 | |||||||

| 姿勢 | 水平 | 垂直 | ||||||

|---|---|---|---|---|---|---|---|---|

| 速度 | 加速度(G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 30 | 30 | 28 | 26 | 24 | 24 | 24 | 24 |

| 35 | 30 | 30 | 28 | 26 | 24 | 24 | 24 | 24 |

| 70 | 30 | 28 | 24 | 22 | 20 | 24 | 22 | 20 |

| 105 | 25 | 22 | 20 | 18 | 16 | 22 | 20 | 16 |

| 140 | 20 | 18 | 16 | 12 | 10 | 16 | 14 | 10 |

| 175 | 14 | 12 | 6 | 9 | 4 | |||

| 210 | 7 | 4 | ||||||

高出力設定無効 可搬質量の単位はkgです。空欄は動作不可となります。

| 姿勢 | 水平 | 垂直 | |

|---|---|---|---|

| 速度 | 加速度(G) | ||

| (mm/s) | 0.3 | 0.7 | 0.3 |

| 0 | 22 | 18 | 5 |

| 140 | 22 | 18 | 5 |

| 280 | 16 | 14 | 5 |

| 420 | 10 | 4 | |

| 560 | 2 | ||

| 姿勢 | 水平 | 垂直 | |

|---|---|---|---|

| 速度 | 加速度(G) | ||

| (mm/s) | 0.3 | 0.7 | 0.3 |

| 0 | 30 | 26 | 12 |

| 70 | 30 | 26 | 12 |

| 140 | 25 | 18 | 12 |

| 210 | 18 | 10 | 3.5 |

| 280 | 4 | ||

| 姿勢 | 水平 | 垂直 | |

|---|---|---|---|

| 速度 | 加速度(G) | ||

| (mm/s) | 0.3 | 0.7 | 0.3 |

| 0 | 30 | 26 | 20 |

| 35 | 30 | 26 | 20 |

| 70 | 25 | 18 | 20 |

| 105 | 20 | 12 | 10 |

ストロークと最高速度

(単位はmm/s)

| リード (mm) | 接続 コントローラー | 40~290 (mm) | 340 (mm) | 390 (mm) |

|---|---|---|---|---|

| 16 | 高出力有効 | 700<560> | 600<560> | |

| 高出力無効 | 560<280> | |||

| 8 | 高出力有効 | 420<350> | 365<350> | 300 |

| 高出力無効 | 280<210> | |||

| 4 | 高出力有効 | 210 | 180 | 150 |

| 高出力無効 | 105 | |||

(注) < >内は垂直使用の場合です。

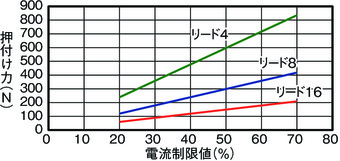

押付け力と電流制限値の相関図

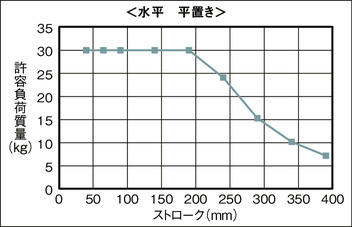

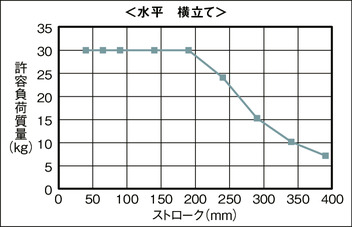

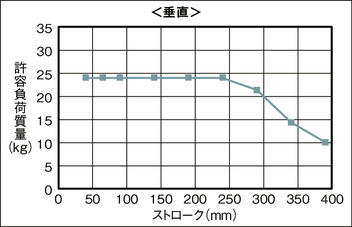

ストローク別許容負荷質量

(注) 許容負荷質量の算出の条件:加速度によるモーメントを考慮したガイド走行寿命5,000kmとなる負荷重量(加速度0.5G、速度500m/s)

水平 平置き

水平 横立て

垂直

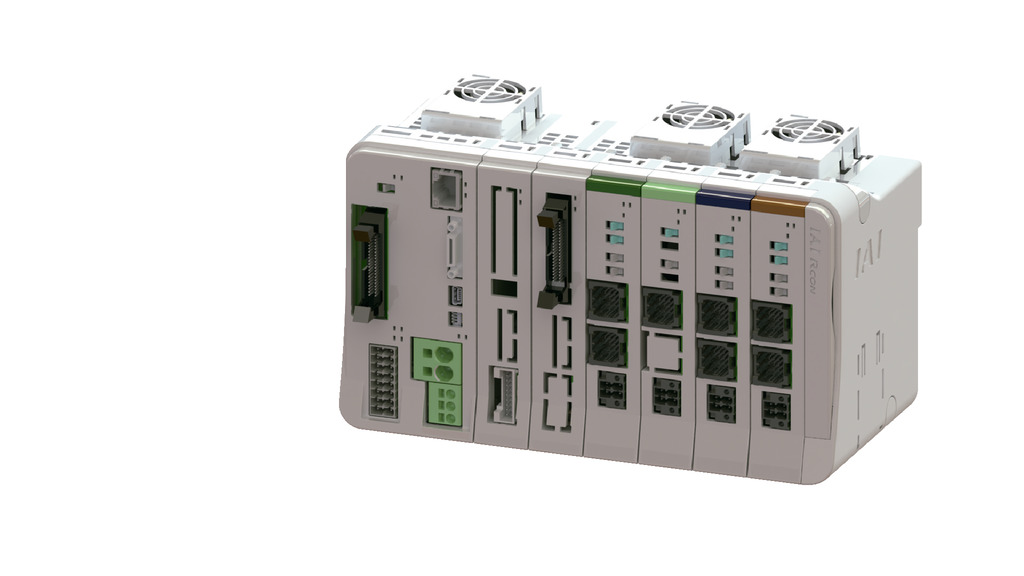

適応コントローラー

本ページのアクチュエーターは下記のコントローラーで動作が可能です。ご使用になる用途に応じたタイプをご選択ください。

| 名称 | 外観 | 最大接続 可能軸数 | 電源電圧 | 制御方法 | 最大位置決め点数 | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ポジショナー | パルス列 | プログラム | ネットワーク ※選択 | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MCON-C/CG |  | 8 | DC24V | - | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | ● | ● | ● | 256 |

| MSEL-PC/PG |  | 4 | 単相AC 100~230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CB/CGB |  | 1 | DC24V | ● ※選択 | ● ※選択 | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (ネットワーク仕様は768) |

| PCON-CYB/PLB/POB |  | 1 | ● ※選択 | ● ※選択 | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

| RSEL |  | 8 | - | - | ● | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 36000 | |

(注) DV、CCなどのネットワーク略称記号については、7-17ページをご確認ください。

(注) RCP6Sシリーズの内蔵コントローラーは、7-103ページをご確認ください。

(注) MCONはオプションで「高出力設定仕様」を指定したものに限り、高出力有効の設定が可能です。高出力有効時の最大接続可能軸数はC:4、LC:3です。

海外規格

選定上の注意

| (1)「メインスペック」の可搬質量は、最大値を表示しています。詳細は「速度・加速度別可搬質量表」をご参照ください。 (2)押付け動作を行う場合は「押付け力と電流制限値の相関図」をご参照ください。押付け力は目安の値です。注意点は1-269ページをご確認ください。 (3)RCP6S(コントローラー内蔵)のリード4/8/16 は、使用周囲温度によって、デューティーの制限が必要です。詳細は1-286ページをご参照ください。 (4)取付姿勢によっては注意が必要です。詳細は1-199ページをご参照ください。 (5)張出し負荷長は、動的許容モーメントの範囲内としてください。 (6)テーブルの変位量は、取扱説明書をご参照ください。 (7)許容負荷質量は機械的制限によりストロークが長くなると低下します。詳細は「ストローク別許容負荷質量」をご参照ください。 (8)静的許容モーメントは、テーブルの上面かつガイドブロック真上(許容モーメントオフセット基準位置)におけるリニアガイドの許容値です。詳細は1-179ページをご確認ください。 |

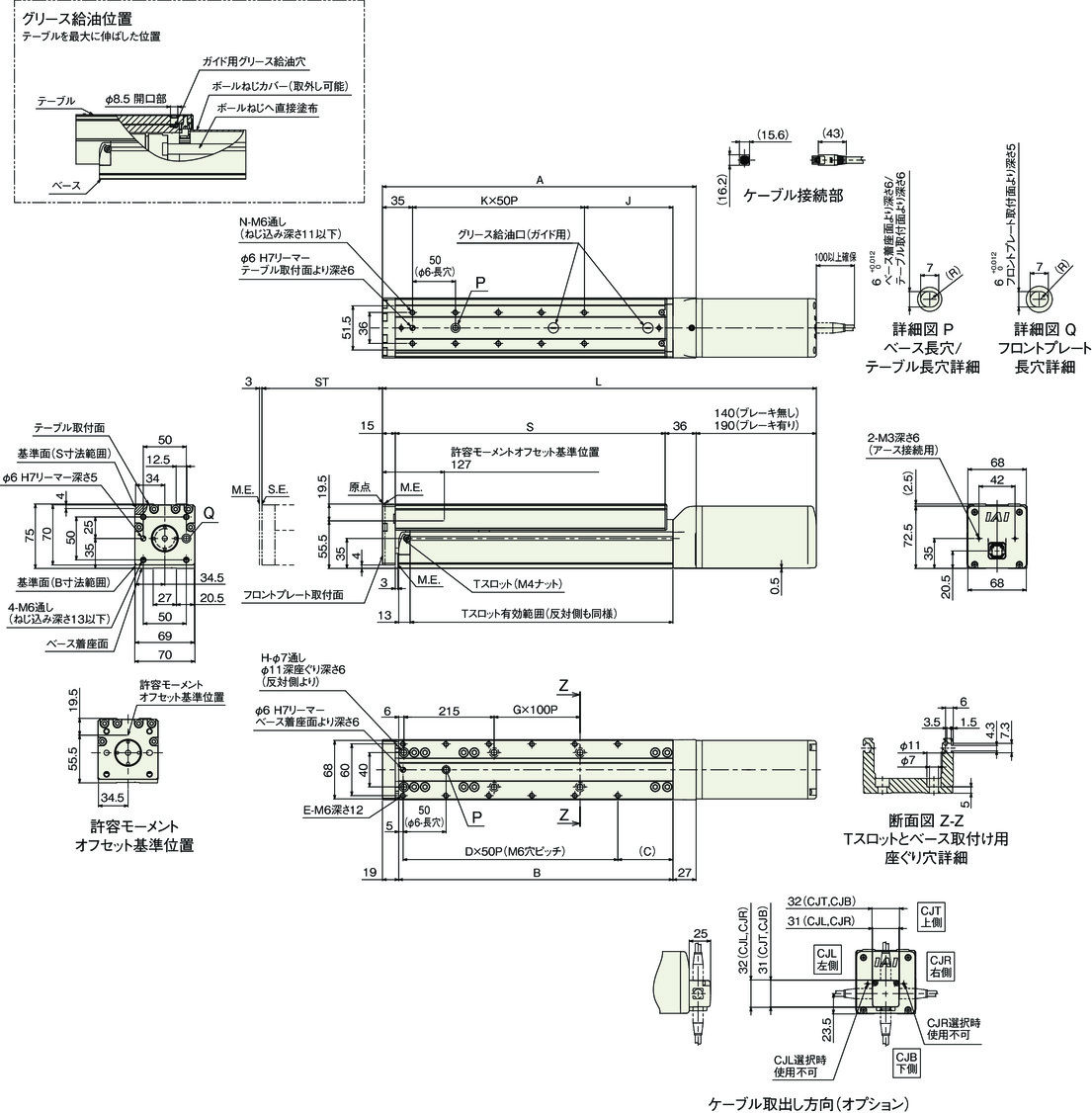

寸法図

RCP6-TA7C(ダブルブロック仕様)

ST:ストローク

M.E.:メカニカルエンド

S.E.:ストロークエンド

(注) 原点復帰を行った場合はテーブルがM.E.まで移動しますので周囲物との干渉にご注意ください。

ストローク別寸法

| ストローク | 40 | 65 | 90 | 140 | 190 | 240 | 290 | 340 | 390 | |

|---|---|---|---|---|---|---|---|---|---|---|

| L | ブレーキ無し | 455 | 480 | 505 | 555 | 605 | 655 | 705 | 755 | 805 |

| ブレーキ有り | 505 | 530 | 555 | 605 | 655 | 705 | 755 | 805 | 855 | |

| A | 315 | 340 | 365 | 415 | 465 | 515 | 565 | 615 | 665 | |

| B | 269 | 294 | 319 | 369 | 419 | 469 | 519 | 569 | 619 | |

| C | 64 | 39 | 64 | 64 | 64 | 64 | 64 | 64 | 64 | |

| D | 4 | 5 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| E | 10 | 12 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | |

| G | 0 | 0 | 0 | 1 | 1 | 2 | 2 | 3 | 3 | |

| H | 4 | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | |

| J | 103 | 78 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | |

| K | 3 | 4 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| N | 8 | 10 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | |

| S | 264 | 289 | 314 | 364 | 414 | 464 | 514 | 564 | 614 | |

ストローク別質量

| ストローク | 40 | 65 | 90 | 140 | 190 | 240 | 290 | 340 | 390 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 質量 (kg) | ブレーキ無し | 5.3 | 5.6 | 5.8 | 6.2 | 6.6 | 7.1 | 7.5 | 8.0 | 8.4 |

| ブレーキ有り | 5.8 | 6.0 | 6.2 | 6.6 | 7.1 | 7.5 | 8.0 | 8.4 | 8.8 | |

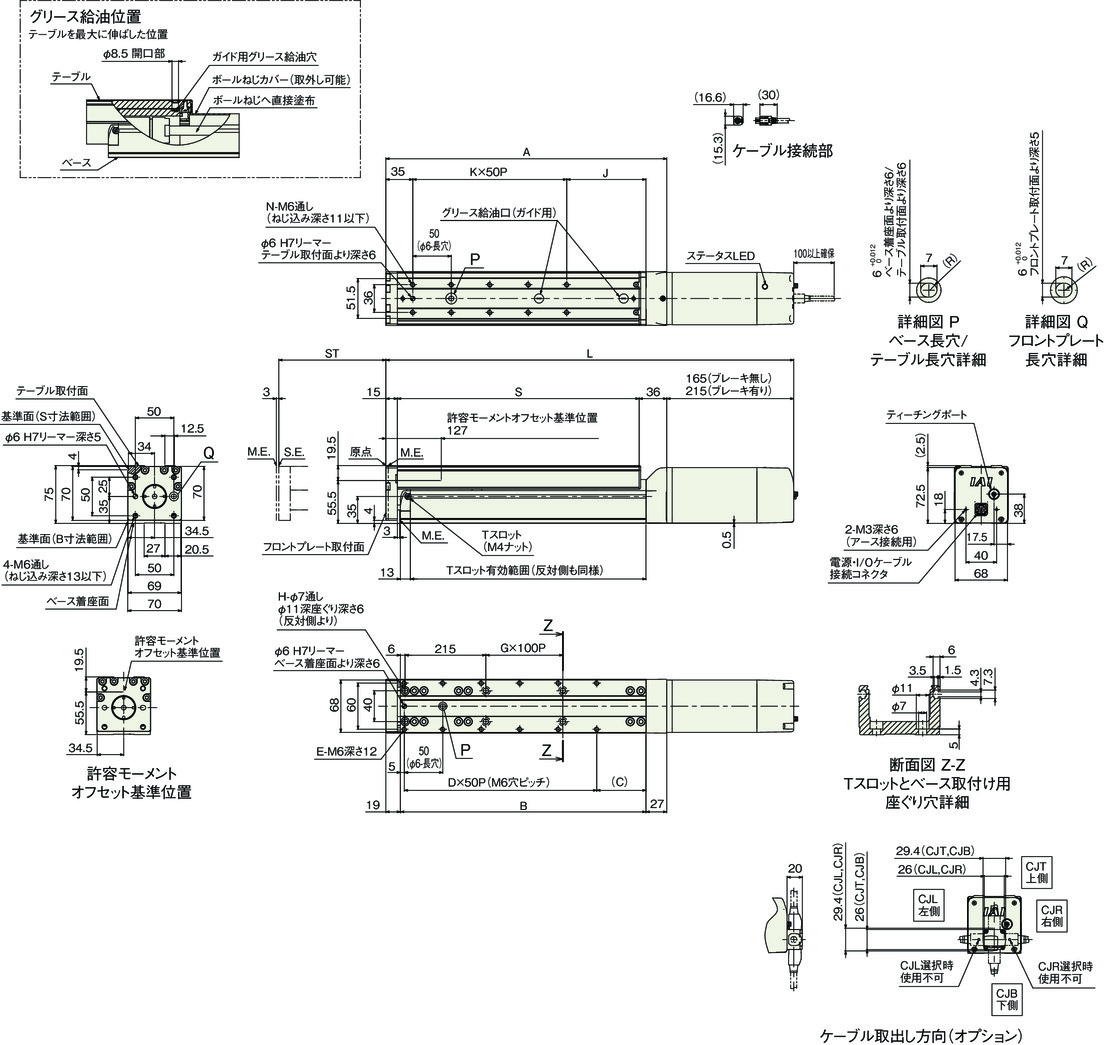

RCP6S-TA7C(ダブルブロック仕様)

ST:ストローク

M.E.:メカニカルエンド

S.E.:ストロークエンド

(注) 原点復帰を行った場合はテーブルがM.E.まで移動しますので周囲物との干渉にご注意ください。

ストローク別寸法

| ストローク | 40 | 65 | 90 | 140 | 190 | 240 | 290 | 340 | 390 | |

|---|---|---|---|---|---|---|---|---|---|---|

| L | ブレーキ無し | 480 | 505 | 530 | 580 | 630 | 680 | 730 | 780 | 830 |

| ブレーキ有り | 530 | 555 | 580 | 630 | 680 | 730 | 780 | 830 | 880 | |

| A | 315 | 340 | 365 | 415 | 465 | 515 | 565 | 615 | 665 | |

| B | 269 | 294 | 319 | 369 | 419 | 469 | 519 | 569 | 619 | |

| C | 64 | 39 | 64 | 64 | 64 | 64 | 64 | 64 | 64 | |

| D | 4 | 5 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| E | 10 | 12 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | |

| G | 0 | 0 | 0 | 1 | 1 | 2 | 2 | 3 | 3 | |

| H | 4 | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | |

| J | 103 | 78 | 103 | 103 | 103 | 103 | 103 | 103 | 103 | |

| K | 3 | 4 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| N | 8 | 10 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | |

| S | 264 | 289 | 314 | 364 | 414 | 464 | 514 | 564 | 614 | |

ストローク別質量

| ストローク | 40 | 65 | 90 | 140 | 190 | 240 | 290 | 340 | 390 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 質量 (kg) | ブレーキ無し | 5.5 | 5.7 | 5.9 | 6.4 | 6.8 | 7.3 | 7.7 | 8.1 | 8.6 |

| ブレーキ有り | 5.9 | 6.2 | 6.4 | 6.8 | 7.3 | 7.7 | 8.1 | 8.6 | 9.0 | |