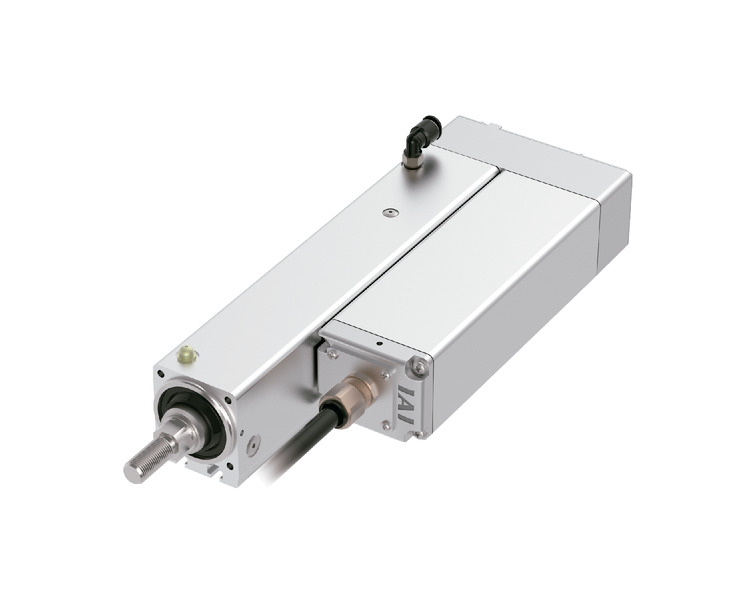

(Note) Photo above shows the motor reversing specification (Motor reversing on the left)(ML).

Main specification

| Heading | Contents | ||||

|---|---|---|---|---|---|

| Lead | Ball screw lead (mm) | 10 | 5 | 2.5 | |

| Horizontal | Load capacity | Maximum load capacity (kg) | 11 | 23 | 40 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 525 | 350 | 175 | |

| Minimum speed (mm/s) | 13 | 7 | 4 | ||

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.5 | ||

| Maximum acceleration/deceleration (G) | 1 | 1 | 1 | ||

| Vertical | Load capacity | Maximum load capacity (kg) | 2 | 4 | 10 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 435 | 350 | 150 | |

| Minimum speed (mm/s) | 13 | 7 | 4 | ||

| Rated acceleration/deceleration (G) | 0.5 | 0.5 | 0.5 | ||

| Maximum acceleration/deceleration (G) | 0.5 | 0.5 | 0.5 | ||

| Pressing motion | Max. pressing thrust (N) | 77 | 155 | 310 | |

| Max. pressing speed (mm/s) | 20 | 20 | 20 | ||

| Brake | Brake specification | Non-excitation electromagnetic brake | |||

| Brake retention force (kgf) | 2 | 4 | 10 | ||

| Stroke | Minimum stroke (mm) | 50 | 50 | 50 | |

| Maximum stroke (mm) | 200 | 200 | 200 | ||

| Stroke pitch (mm) | 50 | 50 | 50 | ||

| Heading | Contents | |

|---|---|---|

| Drive system | Ball screw φ8mm, rolled C10 | |

| Accuracy of Repeating Positioning. | ±0.01mm | |

| Lost motion | 0.1mm or less | |

| Main material | Rod | Aluminum with hard alumite treatment |

| Frame | White alumite treated aluminum | |

| Dust seal | Rubber (NBR) | |

| Actuator cable | Polyvinyl chloride (PVC) | |

| Rod non-rotation accuracy (Note 2) | ±1.0 degrees | |

| Allowable load / torque for the rod tip | 1.0Nm | |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) | |

| Protection grade | IP65(IEC60529/JIS0920) | |

| Vibration resistant/Shock resistant | 4.9m/s2 | |

| Compatible to overseas standards | CE mark, RoHS compliant | |

| Motor type | Pulse motor | |

| Encoder type | Battery-less absolute | |

| Encoder pulse No. | 8192 pulse/rev | |

| Delivery | Written in [Reference for delivery] section of the homepage | |

(Note 2) This is the displacement angle of the rod tip (initial value guideline) when the static allowable torque of the rod tip is applied while the rod is stored in the main body as much as possible.

Stroke and maximum speed

If the environmental temperature exceeds 5℃

(Measured in mm/s)

| Lead (mm) | 50 - 200 (Every 50mm) |

|---|---|

| 10 | 525<435> |

| 5 | 350 |

| 2.5 | 175<150> |

(Note) < > is applicable when operated vertically.

If the environmental temperature is 5℃ or less

(Measured in mm/s)

| Lead (mm) | 50 - 200 (Every 50mm) |

|---|---|

| 10 | 435 |

| 5 | 260 |

| 2.5 | 130 |

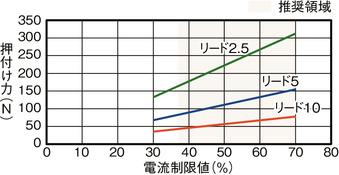

Correlation diagram of pressing force and current limiting value

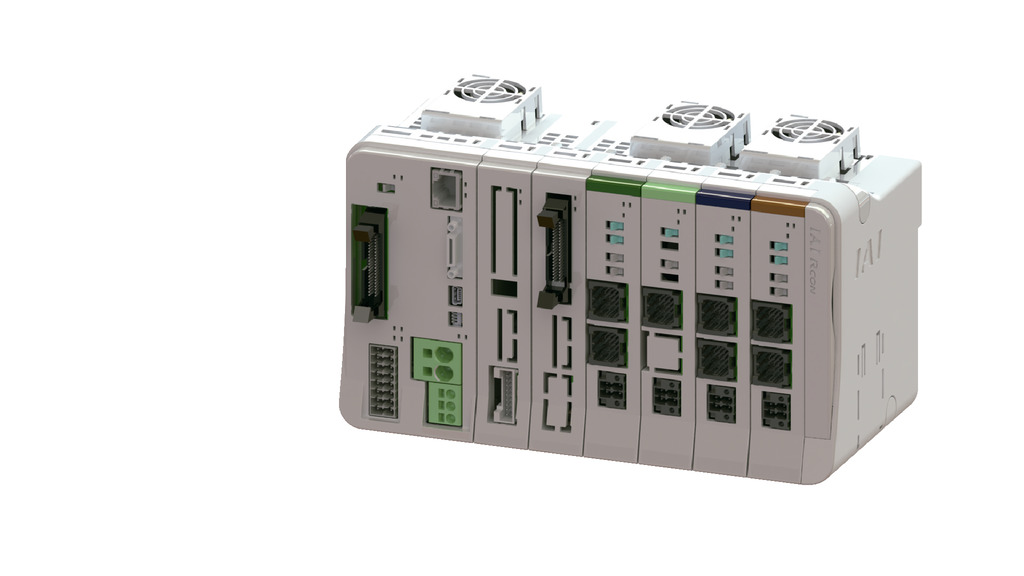

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network *Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MSEL-PC/PG |  | 4 | Single phase AC 100 - 230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CB/CGB |  | 1 | DC24V | ● *Selectable | ● *Selectable | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) |

| PCON-CYB/PLB/POB |  | 1 | ● *Selectable | ● *Selectable | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| RCON |  | 16 (ML3,SSN,ECM is 8) | - | - | - | ● | ● | ● | ● | - | - | ● | ● | ● | ● | ● | ● | 128 (Position data unavailable for ML3, SSN and ECM) | |

| RSEL |  | 8 | - | - | ● | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 36000 | |

(Note) Refer to page 8-17 for network abbreviations such as DV and CC.

(Note) See page 8-139 for built-in controllers for RCP6S series.

Oversea specification

Important notes on selection

| (1) The payload indicated in the "Main Specification" is the maximum value. Please refer to "Load capacity by speed and acceleration table" for further information. (2) Horizontal load capacity shown assumes an operation running with an external guide. Detent mechanism may get damaged if a force was applied to the rod, except towards its moving direction. (3) Please refer to "Correlation diagram of pressing force and power supply limit value" if you may need it to perform pressing operation. Pressing force shown are their standard value. Refer page 1-269 for notes to be considered. (4) The cable joint connector is not drip-proof. Please install it in a place where it will not be exposed to water. (5) The RCP6SW with built-in controller does not have a port for connecting the teaching tool. Connect the teaching tool to the gateway unit to set the parameter data, etc.. (6) Safety measures may be required depending on the attachment orientation. Refer to page 1-261 for further details. |

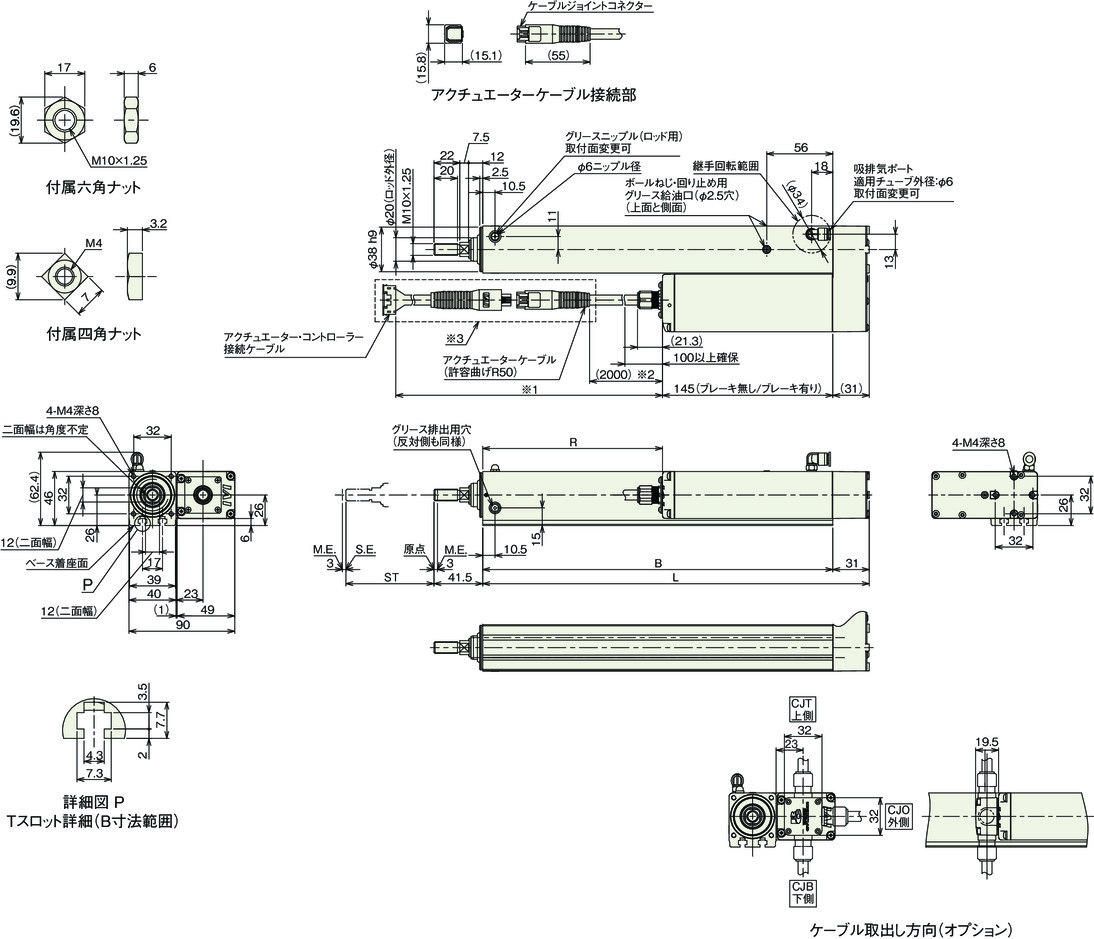

Dimension drawing

RCP6W-RA4R

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

*1 Select the total length of the actuator cable and actuator/controller connection cable so that the total length is 20m or less.

*2 The length of the actuator cable can be selected from 5m, 10m, and 15m as an option.

*3 The cable relay part (cable joint connector) inside the broken line is not drip-proof.

(Note) The rod moves to the M.E. upon returning to origin, so please take precaution that it may not interfere with anything while the returning process is running.

(Note) The direction the width between two flats are facing differs by product.

(Note) Comes with 1 hexagon nut and 4 square nuts.

(Note) Please refer to pages 1-340 for the material of each part.

(Note) Diagram below shows the motor left-reversing specification (ML).

Dimension by stroke length

| Stroke | 50 | 100 | 150 | 200 |

|---|---|---|---|---|

| L | 179 | 229 | 279 | 329 |

| B | 148 | 198 | 248 | 298 |

| R | 3 | 53 | 103 | 153 |

Mass by stroke length

| Stroke | 50 | 100 | 150 | 200 | |

|---|---|---|---|---|---|

| Mass (kg) | Without brake | 1.5 | 1.7 | 1.9 | 2.1 |

| With brake | 1.6 | 1.8 | 2 | 2.2 | |

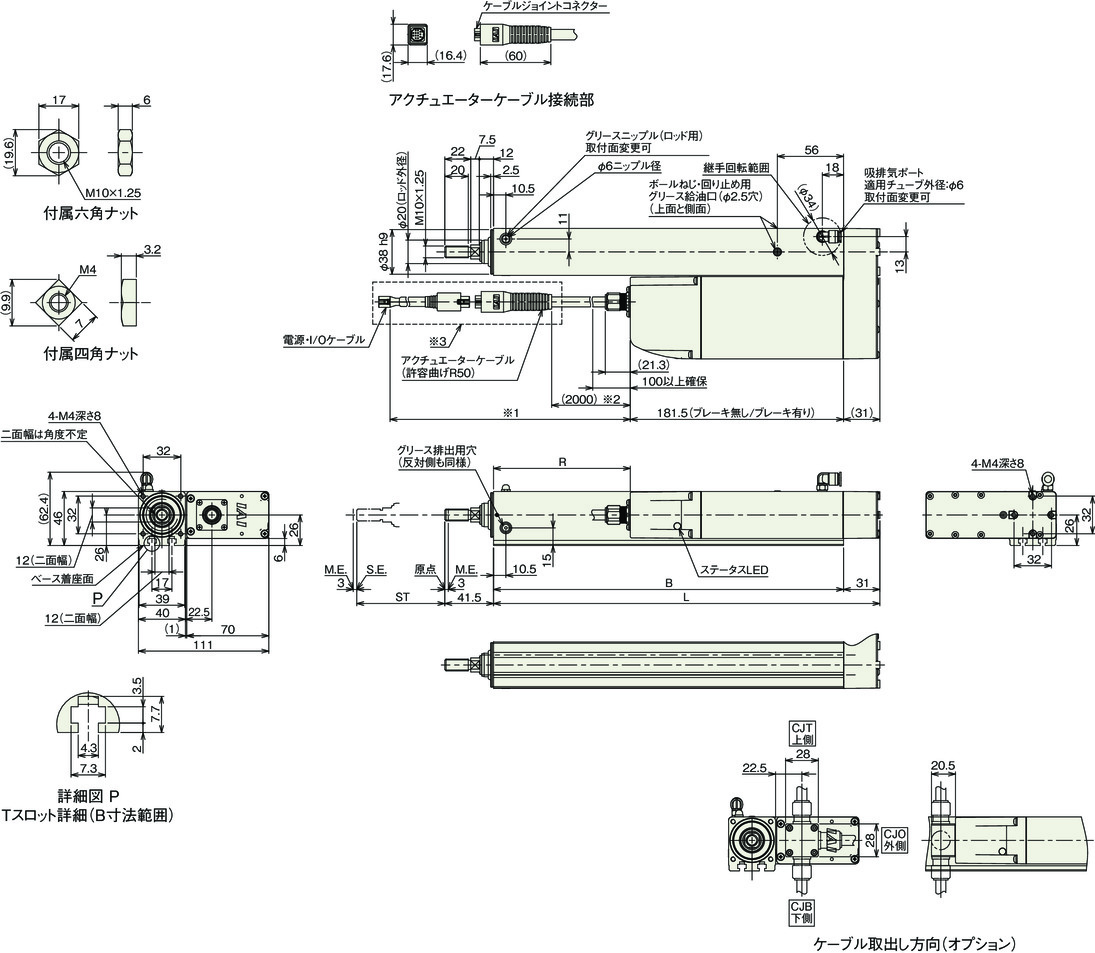

RCP6SW-RA4R

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

*1 Select the total length of the actuator cable and power supply or I/O cable so that the total length is 20m or less.

*2 The length of the actuator cable can be selected from 5m, 10m, and 15m as an option.

*3 The cable relay part (cable joint connector) inside the broken line is not drip-proof.

(Note) The rod moves to the M.E. upon returning to origin, so please take precaution that it may not interfere with anything while the returning process is running.

(Note) The direction the width between two flats are facing differs by product.

(Note) Comes with 1 hexagon nut and 4 square nuts.

(Note) Please refer to pages 1-340 for the material of each part.

(Note) Diagram below shows the motor left-reversing specification (ML).

Dimension by stroke length

| Stroke | 50 | 100 | 150 | 200 |

|---|---|---|---|---|

| L | 179 | 229 | 279 | 329 |

| B | 148 | 198 | 248 | 298 |

| R | -33.5 | 16.5 | 66.5 | 116.5 |

(Note) If the measurement "R" in the figure shows a negative value, it means that the end of the motor unit is located in front of the end face of the base.

Mass by stroke length

| Stroke | 50 | 100 | 150 | 200 | |

|---|---|---|---|---|---|

| Mass (kg) | Without brake | 1.7 | 1.9 | 2.1 | 2.3 |

| With brake | 1.8 | 2 | 2.2 | 2.4 | |

Loadable mass table by speed/acceleration * Refer to page 1-25 for details on high output settings.

High output setting enabled If the environmental temperature exceeds 5℃ Maximum speed varies depending on the transport mass. The base unit for load capacity is kilogram (kg). Empty column refers to inoperable motion.

Lead 10

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 11 | 11 | 9 | 9 | 7 | 2 | 2 | 2 |

| 85 | 11 | 11 | 9 | 9 | 7 | 2 | 2 | 2 |

| 175 | 11 | 11 | 8 | 7 | 5 | 2 | 2 | 2 |

| 260 | 11 | 11 | 7 | 4 | 2 | 2 | 2 | 2 |

| 350 | 11 | 11 | 7 | 3 | 1 | 2 | 2 | 2 |

| 435 | 11 | 10 | 6 | 3 | 1 | 1.5 | 1 | 1 |

| 525 | 4 | 1 | ||||||

Lead 5

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 40 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 85 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 130 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 175 | 23 | 23 | 21 | 16 | 14 | 4 | 4 | 4 |

| 215 | 23 | 23 | 21 | 14 | 12 | 4 | 4 | 4 |

| 260 | 23 | 22 | 18 | 12 | 8 | 4 | 4 | 4 |

| 305 | 22 | 14 | 8 | 6 | 4 | 3 | 3 | 3 |

| 350 | 19 | 5 | 1 | 2 | 1 | 1 | ||

Lead 2.5

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 20 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 40 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 65 | 40 | 40 | 40 | 30 | 30 | 10 | 10 | 10 |

| 85 | 40 | 40 | 35 | 30 | 30 | 10 | 10 | 10 |

| 105 | 40 | 40 | 35 | 30 | 30 | 10 | 6 | 6 |

| 130 | 40 | 40 | 35 | 30 | 30 | 4 | 4 | 4 |

| 150 | 40 | 35 | 35 | 29 | 24 | 2 | 2 | 2 |

| 175 | 33 | 24 | 22 | 19 | 12 | |||

Portable mass table by speed/acceleration (high output setting enabled (5℃ or less))

High output setting enabled If the environmental temperature is 5℃ or less Maximum speed varies depending on the transport mass. The base unit for load capacity is kilogram (kg).

Lead 10

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 11 | 11 | 9 | 9 | 7 | 2 | 2 | 2 |

| 85 | 11 | 11 | 9 | 9 | 7 | 2 | 2 | 2 |

| 175 | 11 | 11 | 8 | 7 | 5 | 2 | 2 | 2 |

| 260 | 11 | 11 | 7 | 4 | 2 | 2 | 2 | 2 |

| 350 | 11 | 11 | 7 | 3 | 1 | 2 | 2 | 2 |

| 435 | 11 | 10 | 6 | 3 | 1 | 1.5 | 1 | 1 |

Lead 5

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 40 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 85 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 130 | 23 | 23 | 21 | 18 | 18 | 4 | 4 | 4 |

| 175 | 23 | 23 | 21 | 16 | 14 | 4 | 4 | 4 |

| 215 | 23 | 23 | 21 | 14 | 12 | 4 | 4 | 4 |

| 260 | 23 | 22 | 18 | 12 | 8 | 4 | 4 | 4 |

Lead 2.5

| Orientation | Horizontal | Vertical | ||||||

|---|---|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||||

| (mm/s) | 0.1 | 0.3 | 0.5 | 0.7 | 1 | 0.1 | 0.3 | 0.5 |

| 0 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 20 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 40 | 40 | 40 | 40 | 35 | 30 | 10 | 10 | 10 |

| 65 | 40 | 40 | 40 | 30 | 30 | 10 | 10 | 10 |

| 85 | 40 | 40 | 35 | 30 | 30 | 10 | 10 | 10 |

| 105 | 40 | 40 | 35 | 30 | 30 | 10 | 6 | 6 |

| 130 | 40 | 40 | 35 | 30 | 30 | 4 | 4 | 4 |