Main specification

| Heading | Contents | ||||

|---|---|---|---|---|---|

| Lead | Ball screw lead (mm) | 10 | 5 | 2.5 | |

| Horizontal | Load capacity | Maximum load capacity (kg) | 5 | 10 | 20 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 380 | 250 | 125 | |

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.2 | ||

| Maximum acceleration/deceleration (G) | 0.3 | 0.3 | 0.2 | ||

| Vertical | Load capacity | Maximum load capacity (kg) | 1.5 | 3 | 6 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 330 | 250 | 125 | |

| Rated acceleration/deceleration (G) | 0.2 | 0.2 | 0.2 | ||

| Maximum acceleration/deceleration (G) | 0.2 | 0.2 | 0.2 | ||

| Thrust | Rated thrust (N) | 89 | 178 | 356 | |

| Brake | Brake specification | Non-excitation electromagnetic brake | |||

| Brake retention force (kgf) | 1.5 | 3 | 6 | ||

| Stroke | Minimum stroke (mm) | 50 | 50 | 50 | |

| Maximum stroke (mm) | 75 | 75 | 75 | ||

| Stroke pitch (mm) | 25 | 25 | 25 | ||

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ8mm, rolled C10 |

| Accuracy of Repeating Positioning. | ±0.02mm |

| Lost motion | 0.1mm and below |

| Life time traveling distance | 5000km, or 50 million round trips |

| Ambient operating temperature and humidity | 0 - 40℃, Max 85% RH and below (No condensation shall occur) |

| Protection grade | IP20 |

| Vibration resistant/Shock resistant | 4.9m/s2 100Hz and below |

| Compatible to overseas standards | CE mark, RoHS compliant |

| Motor type | AC servo motor |

| Encoder type | Incremental/Absolute |

| Encoder pulse No. | Incremental: 1600 pulse/rev Absolute: 16384 pulse/rev |

| Delivery | Written in [Reference for delivery] section of the homepage |

Stroke and maximum speed

(Measured in mm/s)

| Stroke lead | 50 (mm) | 75 (mm) |

|---|---|---|

| 10 | 280<230> | 380<330> |

| 5 | 250<230> | 250 |

| 2.5 | 125 | |

(Note) The value within < > are applicable for those installed vertically.

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network ※Select | |||||||||||||||

| DV | CC | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MSCON-C |  | 6 | Single phase AC 100V/200V | - | - | - | ● | ● | ● | ● | - | - | ● | ● | - | - | - | 256 |

| SCON-CAL/CGAL |  | 1 | ● | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SCON-CB/CGB |  | 1 | ● | ● | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SCON-LC/LCG |  | 1 | - | - | ● | ● | ● | ● | ● | ● | - | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SSEL-CS |  | 2 | ● | - | ● | ● | ● | ● | - | - | - | - | ● | - | - | - | 20000 | |

| XSEL-P/Q |  | 6 | Single phase AC200V Three-phase AC200V | - | - | ● | ● | ● | ● | - | - | - | - | ● | - | - | - | 20000 |

| XSEL-RA/SA |  | 8 | - | - | ● | ● | ● | ● | - | - | - | ● | ● | - | - | - | 55000 (Vary based on type) | |

(Note) Please refer to page 6 -13 for abbreviated names of network (e.g. DV, CC).

(Note) Incremental actuators can't be connected to XSEL-RA/SA or to any of the 5th and/or 6th axis of SCON-CAL/CGAL, MSCON and XSEL-P/Q.

Oversea specification

(Note) CE is optional.

Important notes on selection

| (1) Horizontal load capacity shown assumes an use of guide to free the rod from radial and moment load. Refer information for guide equipped types (→page 1-510) for the flexible volume of the tip, life span and the force allowed towards the rotating direction (allowable rotating torque) of those without a guide. Single guide can't be used here if there is a force applied towards the rotating direction. Double guide shall be used instead. (2) Load capacity assuming an horizontal acceleration of 0.3G (0.2G for lead 2.5) and vertical acceleration of 0.2G, which is their upper limit for acceleration. (3) Available duty depends on the operating condition (e.g.load mass, acceleration/deceleration). Please refer to page 1-448 for further details. (4) Safety measures may be required based on mounting orientation. Please refer to page 1-379 for further information. |

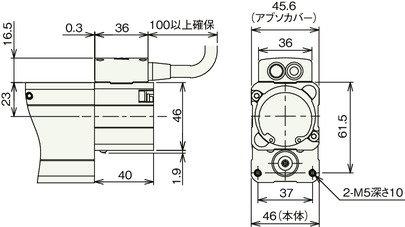

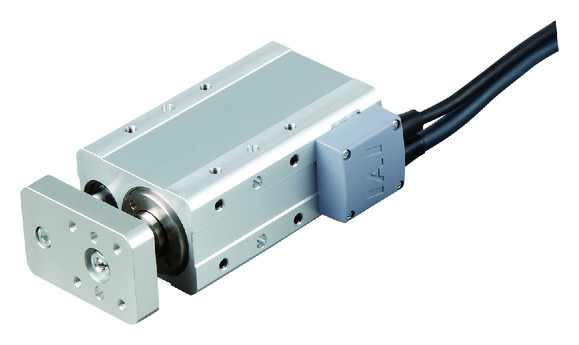

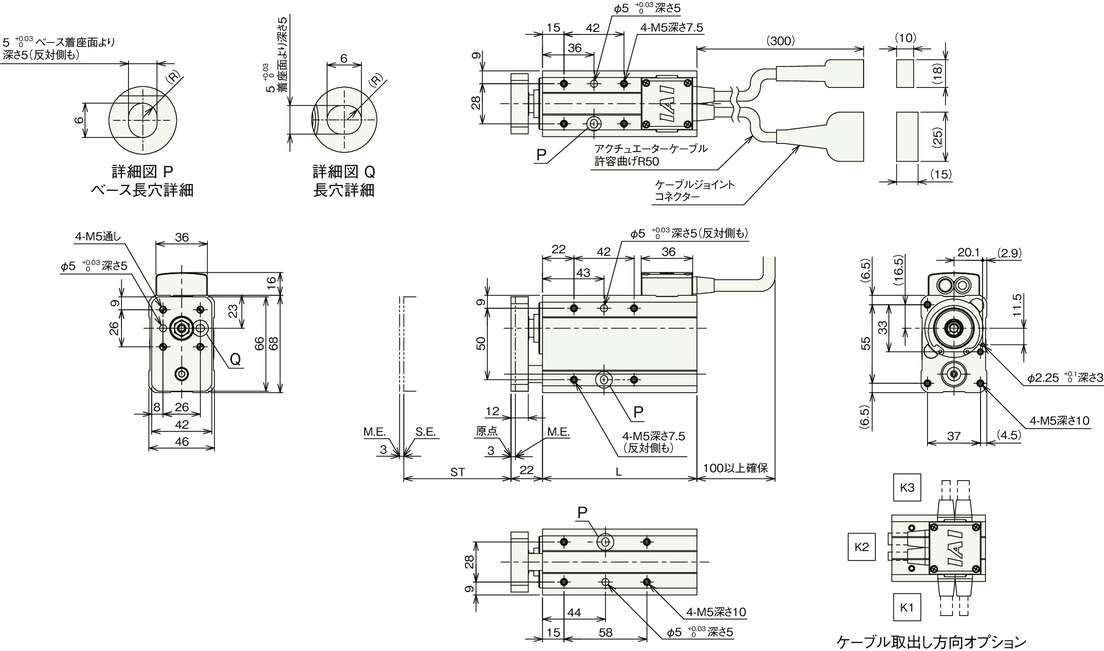

Dimension drawing

Brake present

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

(Note) Connect motor/cable encoder to the cable joint connector. Please refer to page 1-295 for the further details about the cable.

(Note) The rod moves to the M.E. upon returning to origin, so please take precaution that it may not interfere with anything while the returning process is running.

Brake absent

Dimension by stroke length

| Stroke | 50 | 75 |

|---|---|---|

| L | 108 | 133 |

Mass by stroke length

| Stroke | 50 | 75 | |

|---|---|---|---|

| Mass (kg) | Without brake (Incremental specification) | 1.3 | 1.4 |

| Without brake (Absolute specification) | 1.4 | 1.5 | |

| With brake (Incremental specification) | 1.56 | 1.66 | |

| With brake (Absolute specification) | 1.52 | 1.62 | |

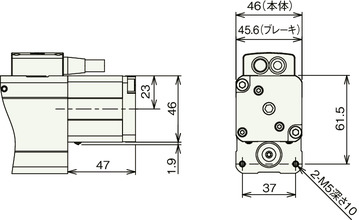

Absolute specification

(Note) The measurement will be the same for both with or without brake.