Main specification

| Heading | Contents | ||||

|---|---|---|---|---|---|

| Lead | Ball screw lead (mm) | 10 | 5 | 2.5 | |

| Horizontal | Load capacity | Maximum load capacity (kg) | 5 | 10 | 20 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 380 | 250 | 125 | |

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.2 | ||

| Maximum acceleration/deceleration (G) | 0.3 | 0.3 | 0.2 | ||

| Vertical | Load capacity | Maximum load capacity (kg) | 1.5 | 3 | 6 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 330 | 250 | 125 | |

| Rated acceleration/deceleration (G) | 0.2 | 0.2 | 0.2 | ||

| Maximum acceleration/deceleration (G) | 0.2 | 0.2 | 0.2 | ||

| Thrust | Rated thrust (N) | 89 | 178 | 356 | |

| Stroke | Minimum stroke (mm) | 50 | 50 | 50 | |

| Maximum stroke (mm) | 75 | 75 | 75 | ||

| Stroke pitch (mm) | 25 | 25 | 25 | ||

| Heading | Contents | |

|---|---|---|

| Drive system | Ball screw φ8mm, rolled C10 | |

| Accuracy of Repeating Positioning. | ±0.02mm | |

| Lost motion | 0.1mm or less | |

| Main material | Rod | - |

| Frame | White alumite treated aluminum | |

| Rubber Cover | Chloroprene Rubber (CR) | |

| Actuator cable | Polyvinyl chloride (PVC) | |

| Rod non-rotation accuracy | - | |

| Life time traveling distance | 5000km, or 50 million round trips | |

| Air purge | Not allowed | |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) | |

| Protection grade | IP52 | |

| Vibration resistant/Shock resistant | 4.9m/s2 | |

| Compatible to overseas standards | CE mark, RoHS compliant | |

| Motor type | AC servo motor | |

| Encoder type | Incremental | |

| Encoder pulse No. | 1600pulse/rev | |

| Delivery | Written in [Reference for delivery] section of the homepage | |

Stroke and maximum speed

(Measured in mm/s)

| Stroke lead | 50 (mm) | 75 (mm) |

|---|---|---|

| 10 | 280<230> | 380<330> |

| 5 | 250<230> | 250 |

| 2.5 | 125 | |

(Note) < > is applicable when operated vertically.

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network *Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| RCON |  | 16 (ML3,SSN,ECM is 8) | DC24V, single phase AC200V, three phase AC200V | - | - | - | ● | ● | ● | ● | - | - | ● | ● | ● | ● | ● | ● | 128 (Position data unavailable for ML3, SSN and ECM) |

| RSEL |  | 8 | - | - | ● | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 36000 | |

| SCON-CB/CGB |  | 1 | Single phase AC 100V/200V | ● | ● | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | ● | 512 (768 for network specification) |

| SSEL-CS |  | 2 | ● | - | ● | ● | ● | - | ● | - | - | - | - | ● | - | - | - | 20000 | |

| XSEL-P/Q |  | 6 | Single phase AC200V Three-phase AC200V | - | - | ● | ● | ● | - | ● | - | - | - | - | ● | - | - | - | 20000 |

(Note) Refer to page 8-17 for network abbreviations such as DV and CC.

(Note) 5th and 6th XSEL-P/Q can't be connected.

Oversea specification

(Note) CE is optional.

Important notes on selection

| (1) The lead screw does not have a detent mechanism. Please be sure to add a detent mechanism (e.g. guide) to the tip of the lead screw when in use. (Without a detent mechanism, the lead screw spins and will be unable to move back or forth.) Do not use floating joints when connecting a detent mechanism to the rod. Please see pages 1-268 for mounting methods and conditions. (2) Horizontal load capacity shown assumes an use of external guide. (3) Load capacity assuming an horizontal acceleration of 0.3G (0.2G for lead 2.5) and vertical acceleration of 0.2G, which is their upper limit for acceleration. (4) The guideline for usable duty varies depending on the operating conditions (transport mass, acceleration/deceleration, etc.). Refer to page 1-282 for further details. (5) Do not apply external force to the rod from any direction except the direction it travels. (6) When using vertically, be careful of interference as the rod descends when the power turns off. (7) Safety measures may be required depending on the attachment orientation. Refer to page 1-261 for further details. |

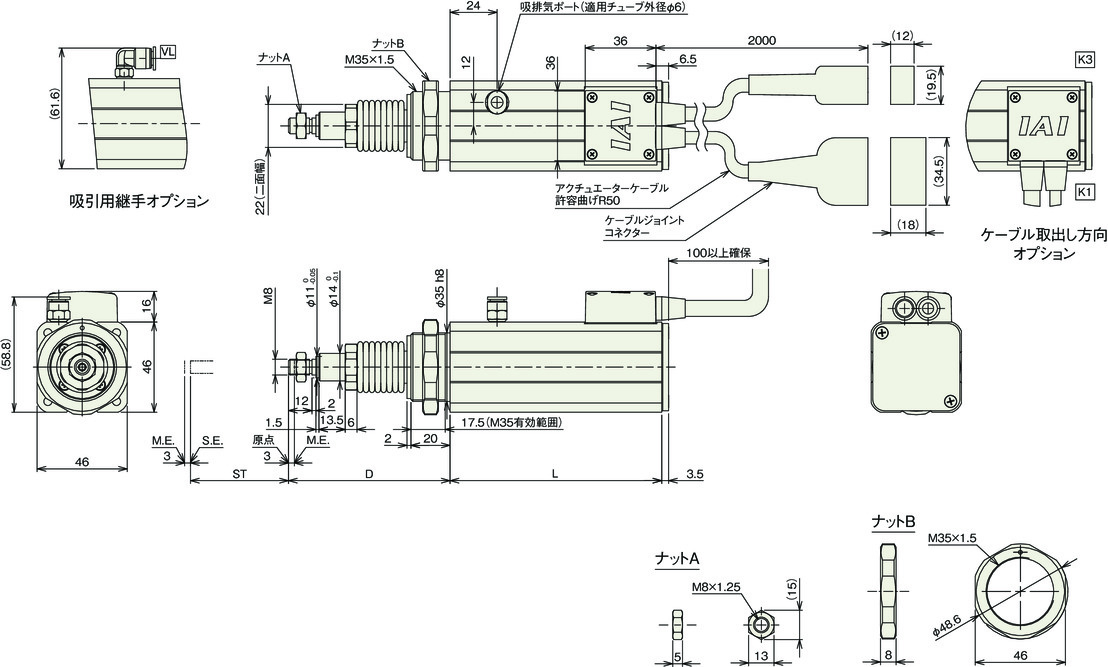

Dimension drawing

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

(Note) The rod moves to M.E. at homing. Please be careful of interference with surrounding objects.

(Note) The direction the width between two flats are facing differs by product.

(Note) Fix a denant mechanism at the external section upon use, for the feeding screw in this product has no detent mechanism.

(Note) The connector at the end of the actuator cable is not subject to the protective structure.

Dimension by stroke length

| Stroke | 50 | 75 |

|---|---|---|

| L | 108 | 133 |

| D | 82.5 | 88.5 |

Mass by stroke length

| Stroke | 50 | 75 | |

|---|---|---|---|

| Mass (kg) | Without brake | 1.06 | 1.18 |