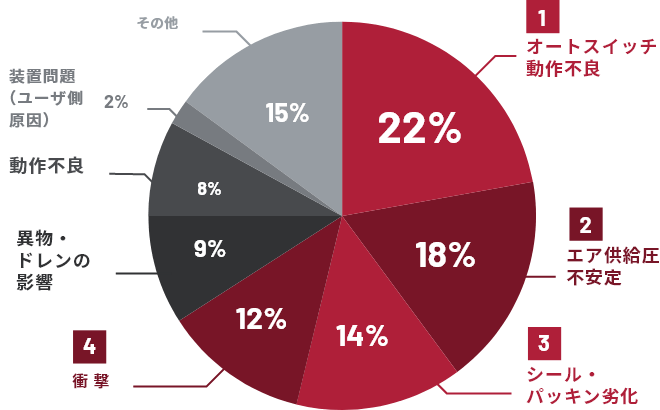

Moment-stop improvement

Leading causes of moment-stops

|

1 Auto switch |

The position where the auto switch turns ON changes due to the following reasons ●Position shift: The auto switch stopper is displaced due to the impact when the air cylinder operates ●Unstable sensitivity: The position to switch to ON changes depending on the usage environment etc. |

|---|---|

|

2 Unstable air supply |

Speed, cycle time, operation timing, thrust, etc., change due to fluctuations in air pressure |

|

3 Deterioration in |

The sealing performance of the rubber deteriorates due to aging, and the operating characteristics of the air cylinder gradually change |

|

4 Impact |

Workpieces may fall, overturn, or be damaged due to impact during acceleration or stopping |

Analysis of the causes of "moment-stops" caused by air cylinders

(Information based on our survey results)

What is moment-stop?

This refers to the phenomenon in which equipment stops or idles due to general troubles, which could be restored with simple measures.

Air cylinders may cause moment-stop due to various factors, depending on the condition of the equipment.

You can eliminate that moment-stop with IAI's electric actuator!

Let's stop viewing moment-stop as regular events.

Learn more about electric actuators