(Note) Photo above shows the motor reversing specification (Motor reversing on the left)(ML).

Main specification

| Heading | Contents | |||||

|---|---|---|---|---|---|---|

| Lead | Ball screw lead (mm) | 30 | 20 | 10 | 5 | |

| Horizontal | Load capacity | Maximum load capacity (kg) | 20 | 35 | 70 | 80 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 1200 | 975 | 450 | 225 | |

| Minimum speed (mm/s) | 38 | 25 | 13 | 7 | ||

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.3 | 0.3 | ||

| Maximum acceleration/deceleration (G) | 1 | 1 | 0.5 | 0.3 | ||

| Vertical | Load capacity | Maximum load capacity (kg) | 2 | 4 | 25 | 55 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 850 | 650 | 400 | 200 | |

| Minimum speed (mm/s) | 38 | 25 | 13 | 7 | ||

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.3 | 0.3 | ||

| Maximum acceleration/deceleration (G) | 0.5 | 0.5 | 0.5 | 0.3 | ||

| Pressing motion | Max. pressing thrust (N) | 78 | 103 | 235 | 470 | |

| Max. pressing speed (mm/s) | 38 | 25 | 20 | 20 | ||

| Brake | Brake specification | Non-excitation electromagnetic brake | ||||

| Brake retention force (kgf) | 2 | 4 | 25 | 55 | ||

| Stroke | Minimum stroke (mm) | 350 | 350 | 350 | 350 | |

| Maximum stroke (mm) | 1100 | 1100 | 1100 | 1100 | ||

| Stroke pitch (mm) | 50 | 50 | 50 | 50 | ||

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ16mm, rolled C10 |

| Accuracy of Repeating Positioning. | Lead 5/10: ±0.02mm, lead 20: ±0.03mm, lead 30: ±0.04mm |

| Lost motion | - (Can't be indicated because this is a 2-point positioning function. ) |

| Base | Dedicated aluminum extrusion material (equivalent to A6063SS-T6) treated with black alumite |

| Linear guide | Infinite linear circulation type |

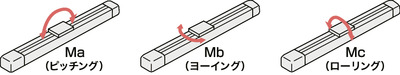

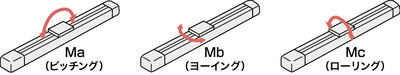

| Allowable static moment value | Ma: 173 N・m |

| Mb: 173 N・m | |

| Mc: 271N・m | |

| Dynamic allowable moment (Note 9) | Ma: 61 N・m |

| Mb: 61 N・m | |

| Mc: 116N・m | |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) |

| Protection grade | IP20 |

| Vibration resistant/Shock resistant | 4.9m/s2 |

| Compatible to overseas standards | CE mark, RoHS compliant |

| Motor type | Pulse motor (□56SP) (power capacity: Max. 6A) |

| Encoder type | Incremental / Battery-less absolute |

| Encoder pulse No. | 800 pulse/rev |

| Delivery | Written in [Reference for delivery] section of the homepage |

(Note 9) Based on standard rated life of 5,000km. Life time travelling distance differs based on operating condition and attached condition. Refer page 1-276 for the operating life.

Slider type moment direction

Load capacity by speed and acceleration table

The base unit for load capacity is kilogram (kg). Empty column refers to inoperable motion.

| Orientation | Horizontal | Vertical | ||||

|---|---|---|---|---|---|---|

| Speed (mm/s) | Acceleration (G) | |||||

| 0.3 | 0.5 | 0.7 | 1 | 0.3 | 0.5 | |

| 0 | 20 | 16 | 13 | 12 | 2 | 2 |

| 200 | 20 | 16 | 13 | 12 | 2 | 2 |

| 450 | 20 | 13 | 12 | 11 | 1 | 1 |

| 650 | 14 | 10 | 9 | 8 | 1 | 1 |

| 850 | 9 | 6 | 4 | 2 | 1 | 1 |

| 1000 | 5 | 3 | 2 | 1 | ||

| 1200 | 1 | |||||

| Orientation | Horizontal | Vertical | ||||

|---|---|---|---|---|---|---|

| Speed | Acceleration (G) | |||||

| (mm/s) | 0.3 | 0.5 | 0.7 | 1 | 0.3 | 0.5 |

| 0 | 35 | 25 | 25 | 25 | 4 | 4 |

| 200 | 35 | 25 | 25 | 25 | 4 | 4 |

| 300 | 35 | 25 | 24 | 16 | 4 | 4 |

| 400 | 35 | 22 | 18 | 12 | 1 | 1 |

| 650 | 18 | 9 | 4 | 3 | 1 | 1 |

| 800 | 10 | 3 | 1 | |||

| 900 | 7 | 1 | ||||

| 975 | 4 | |||||

| Orientation | Horizontal | Vertical | ||

|---|---|---|---|---|

| Speed | Acceleration (G) | |||

| (mm/s) | 0.3 | 0.5 | 0.3 | 0.5 |

| 0 | 70 | 70 | 25 | 25 |

| 100 | 70 | 70 | 25 | 25 |

| 200 | 60 | 50 | 14 | 14 |

| 300 | 45 | 30 | 7 | 7 |

| 400 | 15 | 9 | 2 | 1 |

| 450 | 11 | 2 | ||

| Orientation | Horizontal | Vertical |

|---|---|---|

| Speed (mm/s) | Acceleration (G) | |

| 0.3 | 0.3 | |

| 0 | 80 | 55 |

| 50 | 80 | 55 |

| 75 | 80 | 30 |

| 135 | 80 | 18 |

| 175 | 70 | 11 |

| 200 | 40 | 3 |

| 225 | 10 | |

Stroke and maximum speed

(Measured in mm/s)

| Lead (mm) | 350 - 700 (per 50mm) | 750 (mm) | 800 (mm) | 850 (mm) | 900 (mm) | 950 (mm) | 1000 (mm) | 1050 (mm) | 1100 (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 30 | 1200<850> | 1160<850> | 1040<850> | 940<850> | 860<850> | 780 | 720 | 660 | |

| 20 | 975<650> | 880<650> | 780<650> | 700<650> | 640 | 580 | 530 | 480 | 440 |

| 10 | 450<400> | 430<400> | 380 | 340 | 310 | 280 | 260 | 240 | 220 |

| 5 | 225<200> | 215<200> | 190 | 170 | 150 | 140 | 130 | 115 | 110 |

(Note) < > is applicable when operated vertically.

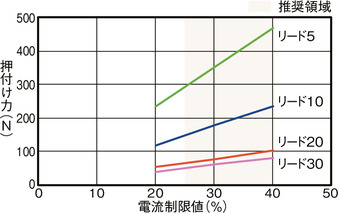

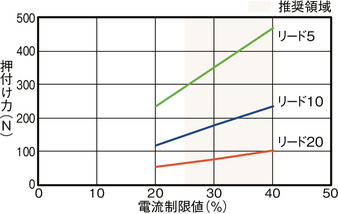

Correlation diagram of pressing force and current limiting value

Adaptive controller

(Note) EC series has their controller built-in themselves. See page 2 769 for details of the built-in controller.

Oversea specification

Important notes on selection

| (1) Maximum speed drops when the stroke length increase, preventing it from reaching the critical revolution value of the ball screws. Use the "Stroke and Max.speed" to check the maximum speed at the stroke you desire. (2) The payload capacity indicated in the "Main specifications" is the maximum value. Please refer to "Load capacity by speed and acceleration table" for further information. (3) When performing push operation, please refer to the "Correlation diagram of push force and current limit value". Pressing force shown are their standard value. Refer page 1- 315 for important points to be taken note of. (4) The duty ratio must be limited according to the ambient temperature of use. Refer to page 1-326 for further details. (5) Requires extra care required depending on the mounting posture. Refer to page 1-307 for further details. (6) The approximate overhang load length is 400mm or less in Ma, Mb, and Mc directions (800mm or less for double slider types). Please refer to page 2-109 for the overhang load length. (7) The center of gravity of the attached object should be less than 1/2 of the overhang distance. Even if the overhang distance and load moment are within the allowable values, if abnormal vibration or noise occurs during operation, loosen the operating conditions before use. (8) Please refer to page 1-293 for the order number and precautions for the double slider type. (9) When connecting the RCON-EC connection specification (ACR) to the EC connection unit (RCON-EC-4), the number of connections that can be made is limited. Refer to page 2-798 for further details. |

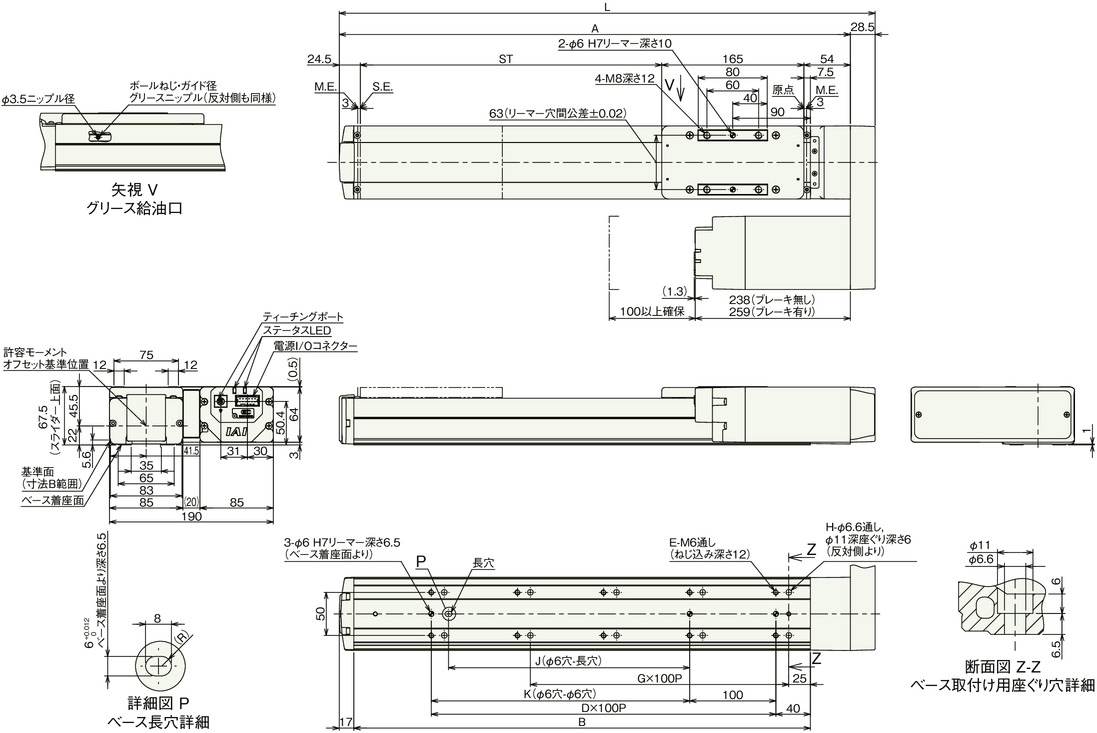

Dimension drawing

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

(Note) Please be careful while returning to the home position, for there is a chance of collision while having the slider returning to the M.E. position.

(Note) Please pay attention to the length of the mounting bolt. When using the mounting screws on the back of the base, if the bolts are too long, they may interfere with internal parts and cause abnormal sliding or damage to parts.

(Note) When fixing the actuator using the through hole in the base, the side cover and stainless steel sheet must be removed first.

(Note) The figure below shows a motor with left-reversing specification (ML).

Dimension by stroke length

| Stroke | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 622 | 672 | 722 | 772 | 822 | 872 | 922 | 972 | 1022 | 1072 | 1122 | 1172 | 1222 | 1272 | 1322 | 1372 |

| A | 593.5 | 643.5 | 693.5 | 743.5 | 793.5 | 843.5 | 893.5 | 943.5 | 993.5 | 1043.5 | 1093.5 | 1143.5 | 1193.5 | 1243.5 | 1293.5 | 1343.5 |

| B | 530 | 580 | 630 | 680 | 730 | 780 | 830 | 880 | 930 | 980 | 1030 | 1080 | 1130 | 1180 | 1230 | 1280 |

| D | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 | 12 |

| E | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 |

| G | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 | 12 |

| H | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 |

| J | 280 | 380 | 380 | 480 | 480 | 580 | 580 | 680 | 680 | 780 | 780 | 880 | 880 | 980 | 980 | 1080 |

| K | 300 | 400 | 400 | 500 | 500 | 600 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | 1000 | 1000 | 1100 |

Mass by stroke length

| Stroke | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass (kg) | Without brake | 6.9 | 7.2 | 7.5 | 7.8 | 8.1 | 8.4 | 8.7 | 9.0 | 9.3 | 9.6 | 9.9 | 10.2 | 10.5 | 10.8 | 11.1 | 11.4 |

| With brake | 7.7 | 8.0 | 8.3 | 8.6 | 8.9 | 9.2 | 9.5 | 9.8 | 10.1 | 10.4 | 10.7 | 11.0 | 11.3 | 11.6 | 11.9 | 12.2 | |

Main specification (double slider type)

| Heading | Contents | ||||

|---|---|---|---|---|---|

| Lead | Ball screw lead (mm) | 20 | 10 | 5 | |

| Horizontal | Load capacity | Maximum load capacity (kg) | 35 | 63 | 73 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | 800 | 450 | 200 | |

| Minimum speed (mm/s) | 25 | 13 | 7 | ||

| Rated acceleration/deceleration (G) | 0.3 | 0.3 | 0.3 | ||

| Maximum acceleration/deceleration (G) | 0.5 | 0.5 | 0.3 | ||

| Vertical | Load capacity | Maximum load capacity (kg) | - | 18 | 48 |

| Speed/ Acceleration/Deceleration | Maximum speed (mm/s) | - | 200 | 175 | |

| Minimum speed (mm/s) | - | 13 | 7 | ||

| Rated acceleration/deceleration (G) | - | 0.3 | 0.3 | ||

| Maximum acceleration/deceleration (G) | - | 0.5 | 0.3 | ||

| Pressing motion | Max. pressing thrust (N) | 103 | 235 | 470 | |

| Max. pressing speed (mm/s) | 25 | 20 | 20 | ||

| Brake | Brake specification | Non-excitation electromagnetic brake | |||

| Brake retention force (kgf) | 4 | 25 | 55 | ||

| Stroke | Min. nominal stroke (mm) | 350 | 350 | 350 | |

| Min. effective stroke (mm) | 150 | 150 | 150 | ||

| Max. nominal stroke (mm) | 1100 | 1100 | 1100 | ||

| Max. effective stroke (mm) | 900 | 900 | 900 | ||

| Stroke pitch (mm) | 50 | 50 | 50 | ||

(Note) Nominal stroke: Stroke indicated in the model

Effective stroke: Actual stroke during operation

(Note) Lead 20 can't be installed vertically.

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ16mm, rolled C10 |

| Accuracy of Repeating Positioning. | Lead 5/10: ±0.02mm, lead 20: ±0.03mm |

| Lost motion | - (Can't be indicated because this is a 2-point positioning function. ) |

| Base | Dedicated aluminum extrusion material (equivalent to A6063SS-T6) treated with black alumite |

| Linear guide | Infinite linear circulation type |

| Allowable static moment value | Ma: 1560 N・m |

| Mb: 1560 N・m | |

| Mc: 542 N・m | |

| Dynamic allowable moment (Note 10) | Ma: 449 N・m |

| Mb: 449 N・m | |

| Mc: 188 N・m | |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) |

| Protection grade | IP20 |

| Vibration resistant/Shock resistant | 4.9m/s2 |

| Compatible to overseas standards | CE mark, RoHS compliant |

| Motor type | Pulse motor (□56SP) (power capacity: Max. 6A) |

| Encoder type | Incremental / Battery-less absolute |

| Encoder pulse No. | 800 pulse/rev |

| Delivery | Written in [Reference for delivery] section of the homepage |

(Note 10) Based on standard rated life of 5,000km. Life time travelling distance differs based on operating condition and attached condition. Refer page 1-276 for the operating life.

Slider type moment direction

Payload table by speed/acceleration (double slider type)

The base unit for load capacity is kilogram (kg). Empty column refers to inoperable motion.

| Orientation | Horizontal | Vertical | ||

|---|---|---|---|---|

| Speed (mm/s) | Acceleration (G) | |||

| 0.3 | 0.5 | 0.3 | 0.5 | |

| 0 | 35 | 25 | ||

| 200 | 35 | 25 | ||

| 300 | 35 | 25 | ||

| 400 | 28 | 15 | ||

| 650 | 13 | 2 | ||

| 800 | 3 | |||

| Orientation | Horizontal | Vertical | ||

|---|---|---|---|---|

| Speed (mm/s) | Acceleration (G) | |||

| 0.3 | 0.5 | 0.3 | 0.5 | |

| 0 | 63 | 63 | 18 | 18 |

| 100 | 63 | 63 | 18 | 18 |

| 200 | 53 | 42 | 7 | 7 |

| 300 | 38 | 23 | ||

| 400 | 8 | 2 | ||

| 450 | 4 | |||

| Orientation | Horizontal | Vertical |

|---|---|---|

| Speed (mm/s) | Acceleration (G) | |

| 0.3 | 0.3 | |

| 0 | 73 | 48 |

| 50 | 73 | 48 |

| 75 | 73 | 23 |

| 135 | 73 | 11 |

| 175 | 50 | 4 |

| 200 | 20 | |

Stroke and the maximum speed (double slider type)

(Measured in mm/s)

| Lead (mm) | Call stroke | 350~700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Effective stroke | 150~500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | |

| (per 50mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 20 | 800 | 780 | 700 | 640 | 580 | 530 | 480 | 440 | ||

| 10 | 450<200> | 430<200> | 380<200> | 340<200> | 310<200> | 280<200> | 260<200> | 240<200> | 220<200> | |

| 5 | 200<175> | 200<175> | 190<175> | 170 | 150 | 140 | 130 | 115 | 110 | |

(Note) < > is applicable when operated vertically.

(Note) Nominal stroke: Stroke indicated in the model

Effective stroke: Actual stroke during operation

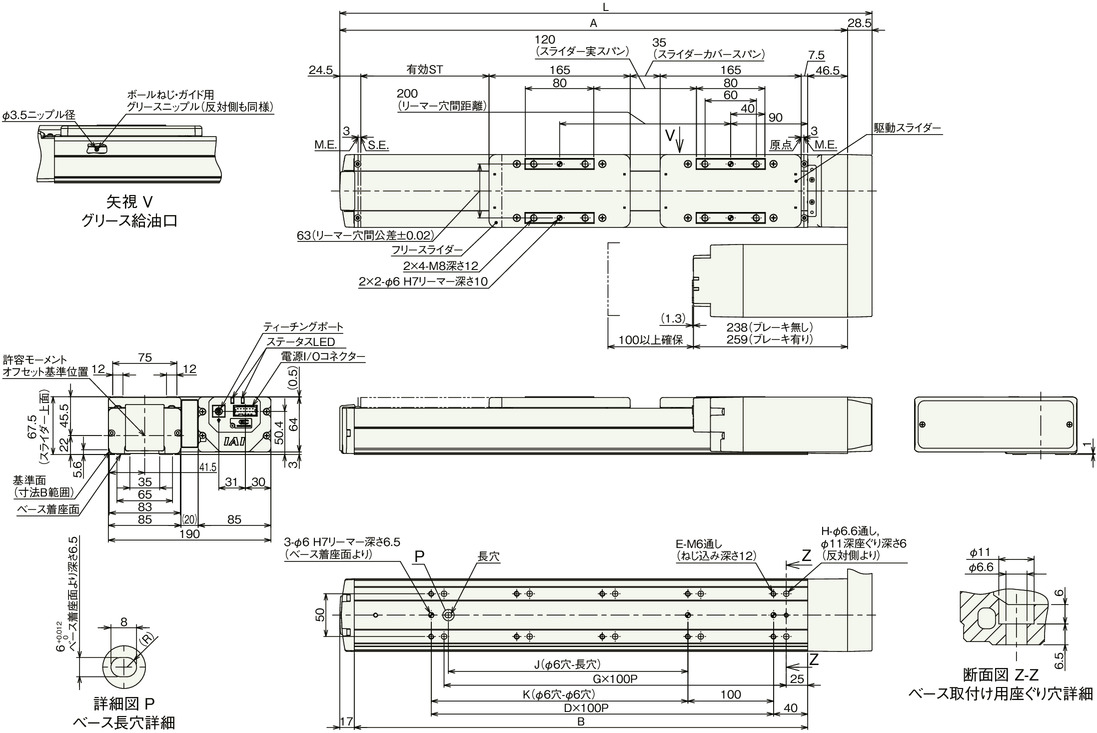

Dimension drawing (double slider type)

ST: Stroke

M.E.: Mechanical end

S.E.: Stroke end

Drawing (double slider type)

(Note) Please be careful while returning to the home position, for there is a chance of collision while having the slider returning to the M.E. position.

(Note) Please pay attention to the length of the mounting bolt. When using the mounting screws on the back of the base, if the bolts are too long, they may interfere with internal parts and cause abnormal sliding or damage to parts.

(Note) Connect the sliders based on the reamer hole distance or the slider cover span listed in the dimension diagram.

(Note) When fixing the actuator using the through hole in the base, the side cover and stainless steel sheet must be removed first.

Dimension by stroke length

| Call stroke | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Effective stroke | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 |

| L | 622 | 672 | 722 | 772 | 822 | 872 | 922 | 972 | 1022 | 1072 | 1122 | 1172 | 1222 | 1272 | 1322 | 1372 |

| A | 593.5 | 643.5 | 693.5 | 743.5 | 793.5 | 843.5 | 893.5 | 943.5 | 993.5 | 1043.5 | 1093.5 | 1143.5 | 1193.5 | 1243.5 | 1293.5 | 1343.5 |

| B | 530 | 580 | 630 | 680 | 730 | 780 | 830 | 880 | 930 | 980 | 1030 | 1080 | 1130 | 1180 | 1230 | 1280 |

| D | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 | 12 |

| E | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 |

| G | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 | 12 |

| H | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 |

| J | 280 | 380 | 380 | 480 | 480 | 580 | 580 | 680 | 680 | 780 | 780 | 880 | 880 | 980 | 980 | 1080 |

| K | 300 | 400 | 400 | 500 | 500 | 600 | 600 | 700 | 700 | 800 | 800 | 900 | 900 | 1000 | 1000 | 1100 |

(Note) Nominal stroke: Stroke indicated in the model

Effective stroke: Actual stroke during operation

Mass by stroke length

| Call stroke | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Effective stroke | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | |

| Mass (kg) | Without brake | 7.71 | 8.01 | 8.30 | 8.60 | 8.89 | 9.18 | 9.48 | 9.77 | 10.07 | 10.37 | 10.67 | 10.97 | 11.27 | 11.57 | 11.87 | 12.17 |

| With brake | 8.53 | 8.83 | 9.12 | 9.42 | 9.71 | 10.01 | 10.30 | 10.59 | 10.89 | 11.19 | 11.49 | 11.79 | 12.09 | 12.39 | 12.69 | 12.99 | |

(Note) This is the mass of the single slider type plus a free slider weighing 0.79kg.

Correlation diagram of push force and current limit value (double slider type)

(Note) Same value as the single slider type.