Actuator specification

| Model | Lead (mm) | Connecting controller | Maximum Load Capacity | Stroke (mm) | |

|---|---|---|---|---|---|

| Horizontal (kg) | Vertical (kg) | ||||

| RCP5CR-SA7C-WA-56P-24-①-②-③-④ | 24 | High Output Enabled | 20 | 3 | 50 - 800 (Every 50mm) |

| High Output Disabled | 18 | 2 | |||

| RCP5CR-SA7C-WA-56P-16-①-②-③-④ | 16 | High Output Enabled | 40 | 8 | |

| High Output Disabled | 35 | 5 | |||

| RCP5CR-SA7C-WA-56P-8-①-②-③-④ | 8 | High Output Enabled | 45 | 16 | |

| High Output Disabled | 40 | 10 | |||

| RCP5CR-SA7C-WA-56P-4-①-②-③-④ | 4 | High Output Enabled | 45 | 25 | |

| High Output Disabled | 40 | 15 | |||

Code description ① Stroke ② Applicable controller ③ Cable length ④ Options

| Lead (mm) | Connecting controller | 50 - 550 (Every 50mm) | 600 (mm) | 650 (mm) | 700 (mm) | 750 (mm) | 800 (mm) | Suction amount (Nℓ/min) |

|---|---|---|---|---|---|---|---|---|

| 24 | High Output Enabled | 1200 | 1145 | 1000 | 885 | 785 | 90 | |

| High Output Disabled | 800 | 785 | ||||||

| 16 | High Output Enabled | 980 <840> | 875 <840> | 755 | 660 | 585 | 520 | 70 |

| High Output Disabled | 560 | 520 | ||||||

| 8 | High Output Enabled | 490 | 430 | 375 | 325 | 290 | 255 | 40 |

| High Output Disabled | 280 | 255 | ||||||

| 4 | High Output Enabled | 245 <210> | 215 <210> | 185 | 160 | 140 | 125 | 30 |

| High Output Disabled | 140 | 125 | ||||||

(Measured in mm/s)

(Note) < > is applicable when operated vertically.

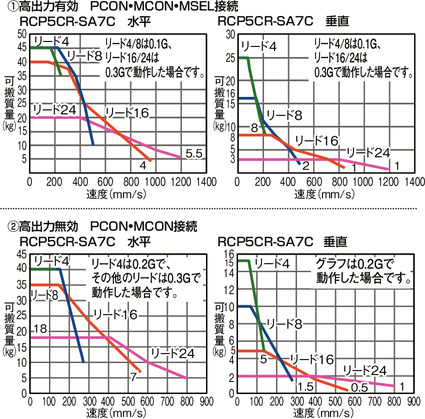

Correlation diagram of speed and load capacity

Actuator specification

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ12mm, rolled C10 |

| Positioning repeatability (Note 1) | ±0.02mm [±0.03] |

| Lost motion | 0.1mm or less |

| Base | Material: White alumite treated aluminum |

| Allowable static moment value | Ma direction 51.2N・m Mb direction 73.1N・m Mc direction 148N・m |

| Allowable dynamic moment (Note2) | Ma direction 11.6N・m Mb direction 16.6N・m Mc direction 33.7N・m |

| Cleanliness | Class 10 (Fed.Std.209D), equivalent to class 2.5 (ISO 14644-1 standard) |

| Ambient operating temperature\humidity | 0 - 40℃, 85%RH or less (no condensation) |

(Note 1) [ ] is for lead 24.

(Note 2) Based on standard rated life of 5,000km. Life time travelling distance differs based on operating condition and attached condition.

Refer page 1-180 for the operating life.

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network *Select | ||||||||||||||||

| DV | CC | CIE | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MCON-C/CG |  | 8 | DC24V | - | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | ● | ● | ● | 256 |

| MCON-LC/LCG |  | 6 | - | - | ● | ● | ● | - | ● | ● | - | - | ● | ● | ● | - | - | 256 | |

| MSEL-PC/PG |  | 4 | Single phase AC 100 - 230V | - | - | ● | ● | ● | - | ● | - | - | - | ● | ● | ● | - | - | 30000 |

| PCON-CB/CGB |  | 1 | DC24V | ● *Selectable | ● *Selectable | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) |

| PCON-CYB/PLB/POB |  | 1 | ● *Selectable | ● *Selectable | - | - | - | - | - | - | - | - | - | - | - | - | - | 64 | |

| RCON |  | 16 | - | - | - | ● | ● | ● | ● | - | - | - | ● | ● | ● | - | - | 128 | |

(Note) Refer to page 7-17 for network abbreviation symbols such as DV and CC.

(Note) High-power setting is only available in MCON with an option for "high-power setting specification". The maximum number of connectable axes when high output is enabled is C: 4, LC: 3.

Oversea specification

Important notes on selection

| (1) Load capacity shown in "Actuator specification" refers to its maximum value, for the actual value changes based on its acceleration. Please refer to "RCP5 / Payload capacity table by speed and acceleration" on page 1-441 and 1-442 of the General Catalogue 2017 for further details. (2) Please refer to page 1-387 of general catalogue 2017 for pressing motion. (3) Precaution is required depending on attachment orientation. Refer page 1-199 for further details. (4) The approximate overhang load length is 230mm or less in Ma, Mb and Mc directions. (5) Please refer to the diagram on page 1-16 for the allowable moment direction and overhang load length. |

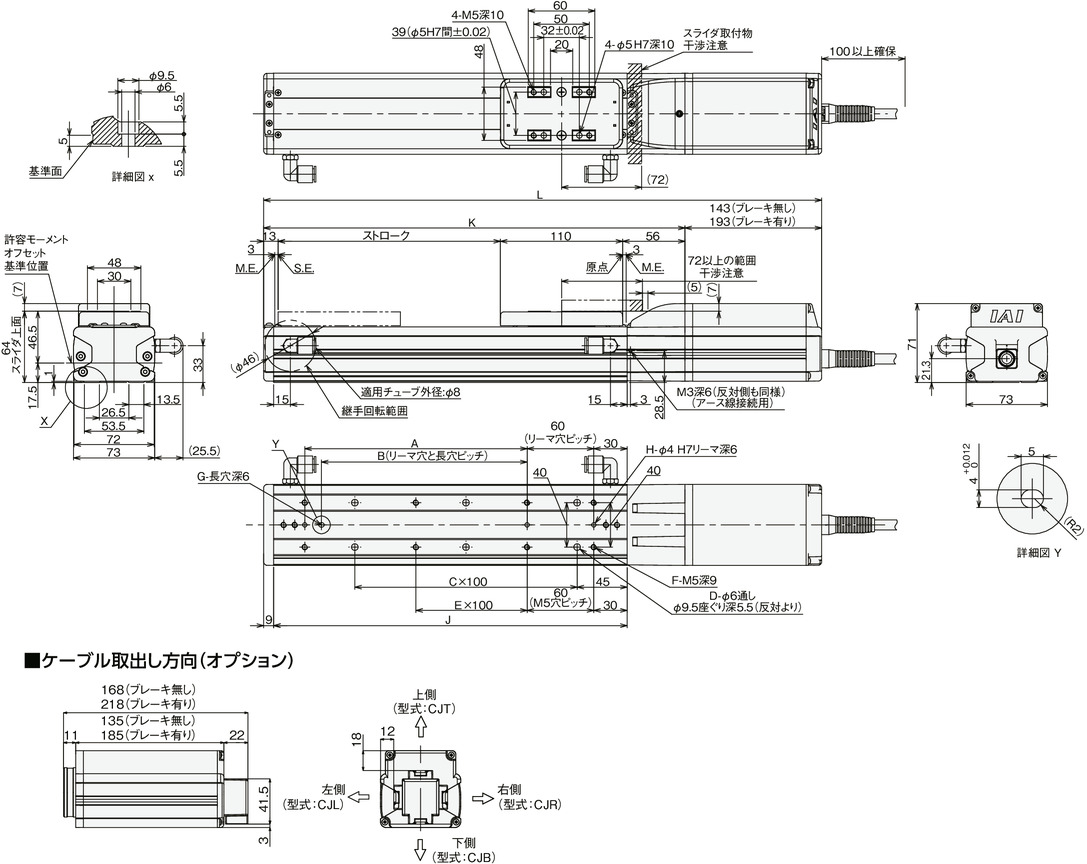

Dimension drawing

M.E.: Mechanical end

S.E.: Stroke end

(Note) Ensure the slider does not collide with other items, for it will return to M.E. after homing process.

Dimension/Mass by stroke

| Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | Without brake | 372 | 422 | 472 | 522 | 572 | 622 | 672 | 722 | 772 | 822 | 872 | 922 | 972 | 1022 | 1072 | 1122 |

| With brake | 422 | 472 | 522 | 572 | 622 | 672 | 722 | 772 | 822 | 872 | 922 | 972 | 1022 | 1072 | 1122 | 1172 | |

| A | 0 | 100 | 100 | 200 | 200 | 300 | 300 | 400 | 400 | 500 | 500 | 600 | 600 | 700 | 700 | 800 | |

| B | 0 | 85 | 85 | 185 | 185 | 285 | 285 | 385 | 385 | 485 | 485 | 585 | 585 | 685 | 685 | 785 | |

| C | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | |

| D | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | |

| E | 0 | 0 | 0 | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | |

| F | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | |

| G | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| H | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| J | 168 | 218 | 268 | 318 | 368 | 418 | 468 | 518 | 568 | 618 | 668 | 718 | 768 | 818 | 868 | 918 | |

| K | 229 | 279 | 329 | 379 | 429 | 479 | 529 | 579 | 629 | 679 | 729 | 779 | 829 | 879 | 929 | 979 | |

| Mass (kg) | Without brake | 3.0 | 3.2 | 3.5 | 3.7 | 3.9 | 4.1 | 4.4 | 4.6 | 4.8 | 5.0 | 5.3 | 5.5 | 5.7 | 5.9 | 6.1 | 6.4 |

| With brake | 3.5 | 3.7 | 4.0 | 4.2 | 4.4 | 4.6 | 4.9 | 5.1 | 5.3 | 5.5 | 5.8 | 6.0 | 6.2 | 6.4 | 6.6 | 6.9 | |