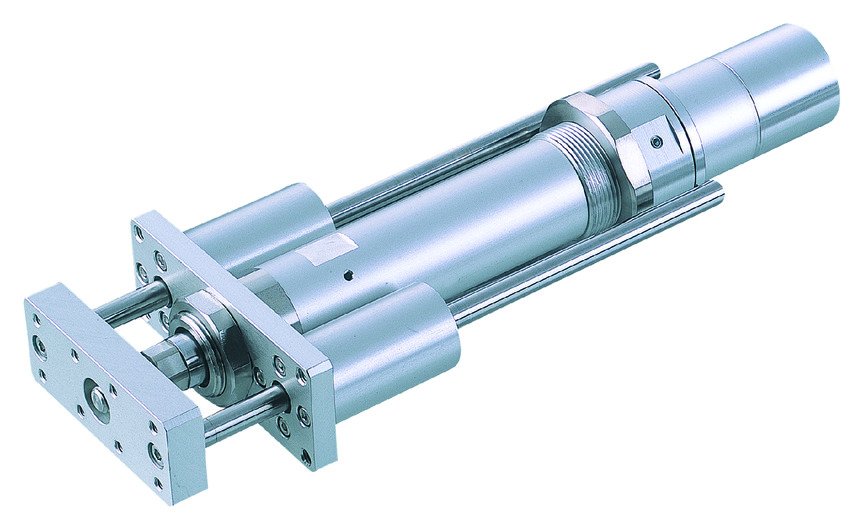

Actuator specification

| Model | Motor output (W) | Lead (mm) | Maximum Load Capacity | Rated thrust (N) | Stroke (mm) | |

|---|---|---|---|---|---|---|

| Horizontal (kg) | Vertical (kg) | |||||

| RCS2-RGD4D-①-20-12-②-T2-③-④ | 20 | 12 | 3.0 | 0.5 | 18.9 | 50 - 300 (50mm intervals) |

| RCS2-RGD4D-①-20-6-②-T2-③-④ | 6 | 6.0 | 1.5 | 37.7 | ||

| RCS2-RGD4D-①-20-3-②-T2-③-④ | 3 | 12.0 | 3.5 | 75.4 | ||

| RCS2-RGD4D-①-30-12-②-T2-③-④ | 30 | 12 | 4.0 | 1.0 | 28.3 | |

| RCS2-RGD4D-①-30-6-②-T2-③-④ | 6 | 9.0 | 2.5 | 56.6 | ||

| RCS2-RGD4D-①-30-3-②-T2-③-④ | 3 | 18.0 | 6.0 | 113.1 | ||

Symbol description ① Encoder type ② Stroke ③ Cable length ④ Option

| Stroke lead | 50 - 300 (50mm intervals) |

|---|---|

| 12 | 600 |

| 6 | 300 |

| 3 | 150 |

(Measured in mm/s)

Actuator specification

| Heading | Contents |

|---|---|

| Drive system | Ball screw φ10mm, rolled C10 |

| Accuracy of Repeating Positioning. | ±0.02mm |

| Lost motion | 0.1mm and below |

| Rod diameter | φ20mm |

| Non-rotational accuracy of rod | ±0.05° |

| Ambient operating temperature and humidity | 0 - 40℃, RH 85% and below (no condensation) |

Adaptive controller

The actuators introduced in this page are controllable using the controllers shown below. Please select their type based on intended usage.

| Name | Appearance | Max. connectable axis No. | Power source voltage | Control method | Maximum positioning points | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Positioner | Pulse train | Program | Network ※Select | |||||||||||||||

| DV | CC | PR | CN | ML | ML3 | EC | EP | PRT | SSN | ECM | ||||||||

| MSCON-C |  | 6 | Single phase AC 100V/200V | - | - | - | ● | ● | ● | ● | - | - | ● | ● | - | - | - | 256 |

| SCON-CAL/CGAL |  | 1 | ● | - | - | ● | ● | ● | ● | ● | - | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SCON-CB/CGB |  | 1 | ● | ● | - | ● | ● | ● | ● | ● | ● | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SCON-LC/LCG |  | 1 | - | - | ● | ● | ● | ● | ● | ● | - | ● | ● | ● | - | - | 512 (768 for network specification) | |

| SSEL-CS |  | 2 | ● | - | ● | ● | ● | ● | - | - | - | - | ● | - | - | - | 20000 | |

| XSEL-P/Q |  | 6 | Single phase AC200V Three-phase AC200V | - | - | ● | ● | ● | ● | - | - | - | - | ● | - | - | - | 20000 |

| XSEL-RA/SA |  | 8 | - | - | ● | ● | ● | ● | - | - | - | ● | ● | - | - | - | 55000 (Vary based on type) | |

(Note) Please refer to page 6 -13 for abbreviated names of network (e.g. DV, CC).

Oversea specification

(Note) CE is optional.

Important notes on selection

| (1) Load capacity assuming an acceleration of 0.3G (0.2G for lead 3), which is its upper limit for acceleration. (2) Available duty depends on the operating condition (e.g.load mass, acceleration/deceleration). Please refer to page 1-448 for further details. (3) Horizontal load capacity shown assumes an use of external guide, without any force applied except towards the moving direction. Refer page 1-515 for the mass the attached guide can bare singly. (4) Safety measures may be required based on mounting orientation. Please refer to page 1-379 for further information. |

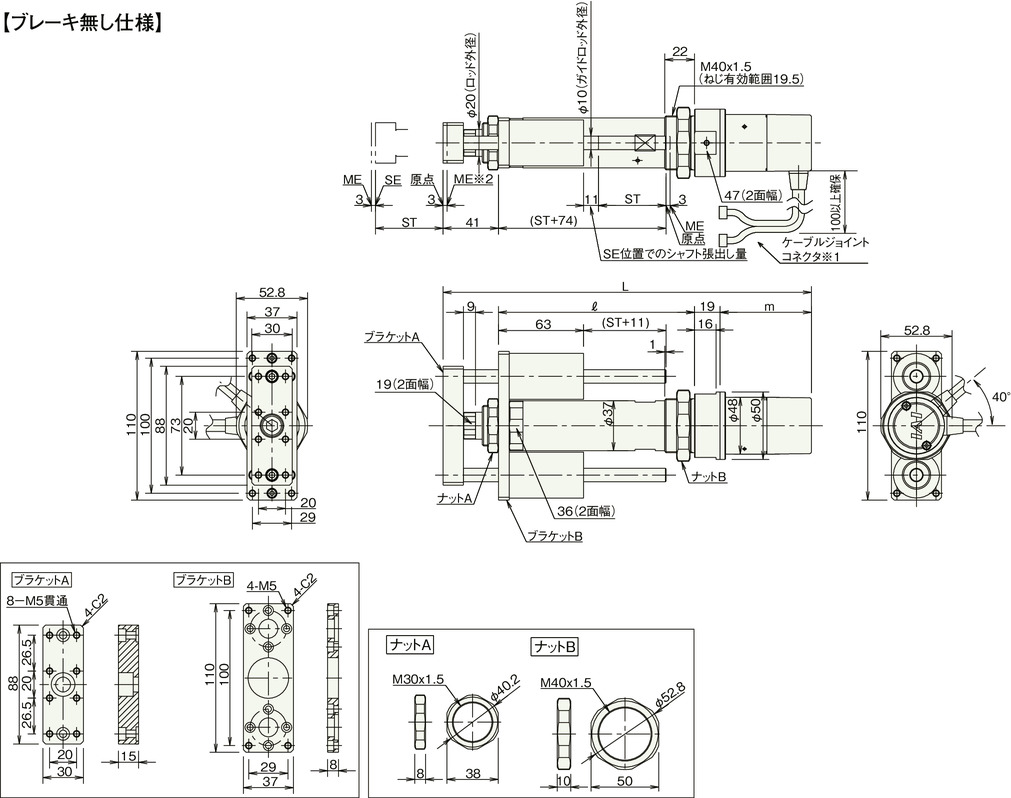

Dimension drawing

ST: Stroke

ME: Mechanical end

SE: Stroke end

※1 Connect a motor/encoder cable. Please refer to page 1-295 for the further details about the cable.

*2 The rod moves to the ME upon returning to origin, so please take precaution that it may not interfere with anything during the process.

(Note) RCS2-RGD4D type has no brake setting.

RCS2-RGD4D (without brake)

| Stroke | 50 | 100 | 150 | 200 | 250 | 300 | |

|---|---|---|---|---|---|---|---|

| L | 20W | 263.5 | 313.5 | 363.5 | 413.5 | 463.5 | 513.5 |

| 30W | 278.5 | 328.5 | 378.5 | 428.5 | 478.5 | 528.5 | |

| ℓ | 145 | 195 | 245 | 295 | 345 | 395 | |

| m | 20W | 58.5 | |||||

| 30W | 73.5 | ||||||

| Mass (kg) | 1.6 | 1.8 | 2.1 | 2.3 | 2.5 | 2.7 | |