Introduces the daily maintenance of the IAI products, using each model representatives as an example. Please use these information as a reference for inspection timing, cleaning method and maintenance method.

Daily maintenance is encouraged for troubles, breakdown preventions.

To begin with

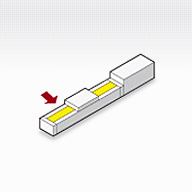

Stainless sheet is one of the components which makes up a Slider type Actuator. This is equipped on the body slit section, which enables the movement of the slider, to prevent foreign particles entering the internal ball screw section.

Stainless sheet equippings makes the structure airtight, and by having the internal pressure maintained to negative through vacuuming, the dust will be minimized, enabling it to be used in clean room.

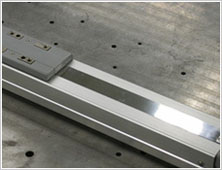

Stainless sheet has an effect to remove dust particles, which leads to frictional wears, by cleaning the surface dirts. Regular maintenance prevents cracks and snappings which results from frictional wears.

This also enables slackings and scratches to be found, making it a reference for tension adjustment and judgings on replacing.

| Heading | Reference of implementation |

|---|---|

| Checking on sight | Appropriate |

| Cleaning | Appropriate |

| Replacing | Mileage: 5,000km |

Stainless steel maintenance items

Damage Condition Checking

Please check the stainless sheet for dirts and its condition of damage.

If the surface was dirty

Please wipe the surface with a soft cloth if it was dirty. (Please use alcohol, or detergent along, if needed to)

If slackings are observed

Please adjust the tension if slackings are observed.

For further details, please refer to the 『Replacing・Adjusting stainless sheet』of 『Maintenance checkup』in the actuator user's manual which came along with the current actuator in use.

User's manual could be downloaded from below. User registration is required in order to download.

Download page of the user's manual

If there were deep cuts, indentations, knocking damages, cracks which may potentially cause a rupture

Please replace the stainless steel, if there were deep cuts, indentations, knocking damages, cracks which may potentially cause a rupture.

(The replacements are responded principally through replacing works by bringing the product to our company, or through our salesman, in your area)

If you were replacing the stainless steel yourself

If you were replacing the stainless steel yourself, please follow the specified procedure in its steps, after reading the user's manual and getting prepared with all needed tools・components.

For further details, please refer to the 『Replacing・Adjusting stainless sheet』of 『Maintenance checkup』in the actuator user's manual which came along with the current actuator in use.

User's manual could be downloaded from below. User registration is required in order to download.

Please inquire through mails

from the URL below.

Stainless steel equipped product

| Classifications | Series | Target product type name |

|---|---|---|

| ROBO Cylinder slider type |

RCP3 | RCP3-SA3C~SA6C,RCP3-SA3R~SA6R |

| RCP2/RCP2CR | RCP2-SA5C~SA7C,RCP2-SA5R~SA7R,RCP2-SS7C/R,RCP2-SS8C/R,RCP2CR-SA5C~SA7C,RCP2CR-SS7C/SS8C,RCP2-HS8C/HS8R,RCP2CR-HS8C | |

| RCA2 | RCA2-SA3C~RCA2-SA6C,RCA2-SA3R~SA6R | |

| RCA/RCACR | RCA-SA4C~SA6C,RCA-SA4D~SA6D,RCA-SA4R~SA6R,RCA-SS4D~SS6D,RCACR-SA4C~SA6C,RCACR-SA5D/SA6D | |

| RCS3 | RCS3-SA8C,RCS3-SS8C,RCS3P-SA8C,RCS3P-SS8C,RCS3CR-SA8C,RCS3CR-SS8C,RCS3PCR-SA8C,RCS3PCR-SS8C | |

| RCS2/RCS2CR | RCS2-SA4C~SA7C,RCS2-SA4D~SA6D,RCS2-SA4R~SA7R,RCS2-SS7C/SS8C,RCS2-SS7R/SS8R,RCS2CR-SA4C~SA7C,RCS2CR-SA5D/SA6D,RCS2CR-SS7C/SS8C | |

| RCL | RCL-SA1L~SA6L,RCL-SM4L~SM6L | |

| Slider type industrial robot |

IS(P)DA/IS(P)DACR | ISDA,ISDACR,ISDACR-ESD,ISPDA,ISPDACR,ISPDACR-ESD |

| LSA | All excluding LSA-L15SM,LSA-L15SS |